102

107774-02 - 4/18

A. Overview

1. Honeywell R7910B Controller

The Honeywell R7910B Controller (“Control”)

contains features and capabilities which help

improve heating system operation, and efficiency.

By including unique capabilities, the Control

can do more, with less field wiring, and fewer

aftermarket controls and components – improving

the operation of both new and replacement boiler

installations.

2. Advanced Touch Screen Display

Home Screen

Boiler status and setup selections are available

from an easy to use LCD Touch Screen Display.

In the event of a fault condition the user is guided

by “blinking” touch buttons to Help screens that

describe the problem. Operation evaluation

and problem-solving is enhanced by historical

capability including lockout history records as

well as boiler and circulator cycle counts and

run time hours.

3. Advanced Modulating Control

The Control modulates the boiler input by varying

the fan speed. As the fan speed increases,

so does the amount of fuel gas drawn into the

blower. As a result, a fairly constant air-fuel ratio

is maintained across all inputs. The Control

determines the input needed by looking at

both current and recent differences between

the measured temperature and the setpoint

temperature. As the measured temperature

approaches the setpoint temperature, the fan will

XIII. Operation

IMPORTANT

This boiler is equipped with a feature that saves energy by reducing the boiler water

temperature as the heating load decreases. This feature is equipped with an override

which is provided primarily to permit the use of an external energy management system

that serves the same function. THIS OVERRIDE MUST NOT BE USED UNLESS AT LEAST

ONE OF THE FOLLOWING CONDITIONS IS TRUE:

• An external energy management system is installed that reduces the boiler water

temperature as the heating load decreases.

• This boiler is not used for any space heating.

• This boiler is part of a modular or multiple boiler system having a total input of

300,000 BTU/hr or greater.

slow down and the input will drop. The Control

also utilizes boiler return water and flue gas

temperatures to adjust fan speed.

4.

HeatMatch

TM

Software

When the boiler is installed with a Sage Zone

Control Panel (Zone Control) into a multiple

zone home the Control uses a patent pending

HeatMatch Software to improve home comfort,

increase component life and save energy. The

Control with the Zone Control detects active

(turned “On”) zones, totals btu/hrs expected

and limits the boiler firing rate to “match” actual

home demand. Instead of simply firing to 100% in

response to a cold supply water temperature the

Control combines heat matching with supply water

temperature control. Additionally, as zones turn

“Off” maximum firing rate is immediately reduced

eliminating the need for supply water temperature

to first increase above setpoint. The result is longer

run times, dramatic reduction in boiler excessive

cycling and higher operating efficiency. Avoiding

extra cycling saves customer fuel dollars (pre

and post purge sends heat up stack) and saves

wear and tear on the boiler. Lowering the boiler’s

firing rate saves fuel dollars by increasing the

amount of flue gas condensation, always the

goal of condensing boiler installations.

5. Built-in Safety Control

The Control includes safety controls designed to

ensure safe and reliable operation. In addition to

flame safety controls the Control includes supply

water temperature, differential water temperature,

and stack temperature safety limits and stepped

modulation responses. Boiler modulation is

adjusted when required to help avoid loss of boiler

operation due to exceeding limits. Additionally,

the Control accepts the field installation of optional

auxiliary safety limits.

Summary of Contents for K2WTC-135

Page 81: ...81 107774 02 4 18 X Domestic Hot Water Piping continued Figure 10 1 Domestic Hot Water Piping...

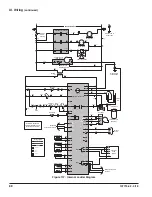

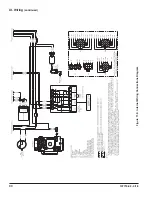

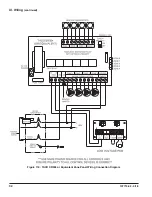

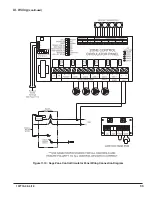

Page 89: ...89 107774 02 4 18 XI Wiring continued...

Page 90: ...90 107774 02 4 18 Figure 11 8 Internal Wiring Connections Diagram XI Wiring continued...

Page 101: ...101 107774 02 4 18 Lighting and Operating Instructions XII Start Up and Checkout continued...

Page 142: ...142 107774 02 4 18 XVI Repair Parts continued...

Page 145: ...145 107774 02 4 18 XVI Repair Parts continued...

Page 148: ...148 107774 02 4 18 XVI Repair Parts continued...

Page 150: ...150 107774 02 4 18 XVI Repair Parts continued...

Page 152: ...152 107774 02 4 18 XVI Repair Parts continued 120 121 122 123 124 125 126 127...

Page 159: ...159 107774 02 4 18 SERVICE RECORD DATE SERVICE PERFORMED...