99

107774-02- 4/18

XII. Start-Up and Checkout

(continued)

To return the boiler to automatic modulation, press AUTO FIRE. Note: If the Auto Fire button is not pressed,

boiler will remain in manual fire for around 10 minutes. After 10 minutes boiler automatically returns to auto-

matic modulation.

At both high and low fire, CO readings should be less than 200 PPM air free. Typical CO

2

and O

2

readings are

shown in Table 12.5A. Final readings should be taken with all doors and covers in place. If adjustments are

needed, make them as follows:

a. With burner at high fire, adjust gas valve throttle (Fig 12.4) as needed to obtain CO

2

(or O

2

) setting shown

in Table 12.5A.

• To reduce the CO

2

(increase the O

2

), turn throttle clockwise.

• To increase the CO

2

(reduce the O

2

), turn throttle counter-clockwise.

Make adjustments in increments of 1/8 to 1/4 turns and allow the boiler at least a minute to respond before

making another adjustment.

b. With the burner at low fire, adjust gas valve offset regulator (Fig 12.4) as needed to obtain CO

2

(or O

2

)

setting shown in Table 12.5A.

• To reduce the CO

2

(increase the O

2

), turn offset regulator counter-clockwise.

• T o increase the CO

2

(reduce the O

2

), turn offset regulator clockwise.

Make adjustments in increments of no more than 1/8 turns and allow the boiler at least a minute to

respond before making another adjustment.

17. Perform a check of the ignition safety shut-off device. With the burner firing, carefully unplug the orange

flame rod wire at the flame rod using a pair of insulated pliers (Figure 12.1). The burner should shut

off immediately.

18. Test any external limits or other controls in accordance with the manufacturer’s instructions.

19. Refer to the Operation Manual to set-up the control for the system in which the boiler is installed. Some

common set-up tasks include:

•

Setting the CH temperature set-point.

•

Defining the system pump operation.

20. Adjust the heating thermostat to its final set point.

WARNING Improper gas valve adjustments can result in unreliable operation, substantial property

damage, personal injury or loss of life due to carbon monoxide (CO) poisoning. Observe the following

precautions:

•

Do not attempt to adjust gas valve without a combustion analyzer.

•

Each boiler is tested at the factory and adjustments to the gas valve are normally not necessary when

operating on natural gas at sea level. Before making any adjustments, make sure that the analyzer is

calibrated and that combustion readings have stabilized.

•

Regulator (“offset”) screw used for low fire adjustment is very sensitive. Adjust no more than 1/8

turn before checking combustion with analyzer. Maximum total regulator adjustment is ± 1 turn from

factory setting.

Summary of Contents for K2WTC-135

Page 81: ...81 107774 02 4 18 X Domestic Hot Water Piping continued Figure 10 1 Domestic Hot Water Piping...

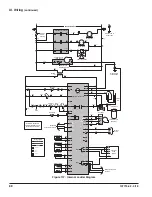

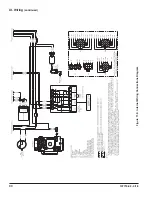

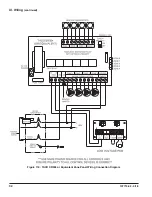

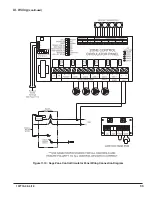

Page 89: ...89 107774 02 4 18 XI Wiring continued...

Page 90: ...90 107774 02 4 18 Figure 11 8 Internal Wiring Connections Diagram XI Wiring continued...

Page 101: ...101 107774 02 4 18 Lighting and Operating Instructions XII Start Up and Checkout continued...

Page 142: ...142 107774 02 4 18 XVI Repair Parts continued...

Page 145: ...145 107774 02 4 18 XVI Repair Parts continued...

Page 148: ...148 107774 02 4 18 XVI Repair Parts continued...

Page 150: ...150 107774 02 4 18 XVI Repair Parts continued...

Page 152: ...152 107774 02 4 18 XVI Repair Parts continued 120 121 122 123 124 125 126 127...

Page 159: ...159 107774 02 4 18 SERVICE RECORD DATE SERVICE PERFORMED...