8

107774-02 - 4/18

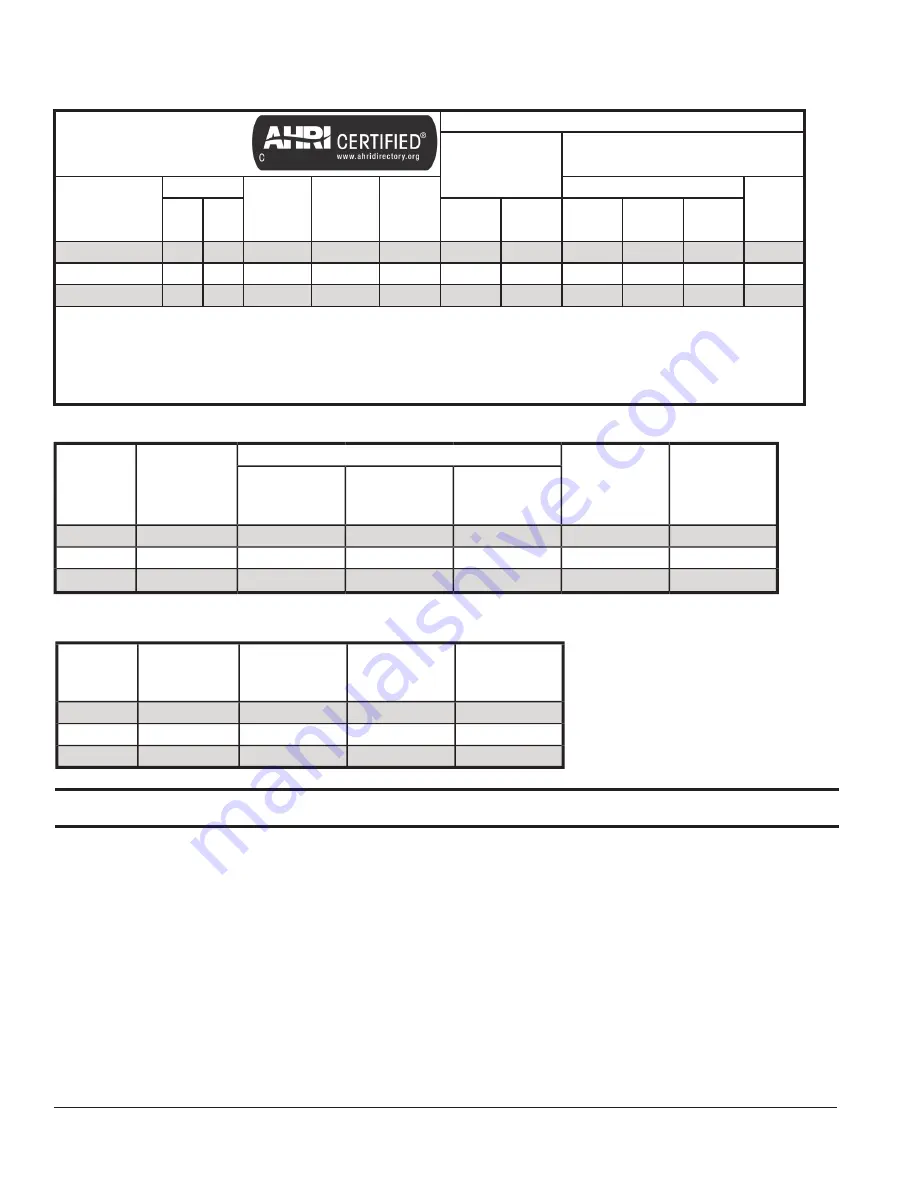

Table 2.2: Performance Specifications

K2WTC Space Heating Ratings

Domestic Hot Water (DHW) Ratings

1

Input, MBH

Hot Water Draw Limits, GPM

Model Number

Input, MBH

Heating

Capacity,

MBH

2

Net AHRI

Water,

MBH

AFUE, %

Max.

3

Min.

4

Min

Max

Min

Max

70°F

77°F

90°F

Rise

Rise

Rise

K2WTC-135B

12

120

112

97

95.0

12

135

3.3

3.0

2.6

0.5

K2WTC-150B

15

150

142

123

95.0

15

150

3.9

3.7

3.1

0.5

K2WTC-180B

18

180

169

147

95.0

18

180

4.5

4.1

3.5

0.5

Notes:

1. DHW ratings are not AHRI certified.

2. The Net AHRI Water Ratings shown are based on a piping and pickup allowance of 1.15. The manufacturer should be consulted before selecting a boiler for

installations having unusual piping and pickup requirements, such as intermittent system operation, extensive piping systems, etc.

3. Maximum draw rates shown are at sea level and minimum vent length. Under other conditions draw rates will be reduced proportionally to the reduction in input.

See Table 2.4 and Appendix A for input de-rate information.

4. Minimum flow rate shown is that required through the boiler to initiate a call for DHW. A higher flow rate may be required through the fixture due to mixing at the

tempering valve and fixture itself.

Table 2.3: Physical Specifications

Model

Size

Fig 2.1 Dim

“A”, (in)

Connection Size (NPT Male)

Boiler Water

Content,

(Gal.)

Net Weight,

(lbs.)

Supply/Return

Hot/Cold

Gas

135

15

1

3/4

1/2

0.53

109

150

19

1

3/4

1/2

0.79

126

180

19

1

3/4

1/2

0.79

126

1.

Safe, reliable operation of this boiler depends upon installation by a professional heating contractor in strict

accordance with this manual and the requirements of the authority having jurisdiction.

• In the absence of an authority having jurisdiction, installation must be in accordance with this manual

and the National Fuel Gas Code, ANSI Z223.1. In Canada, installation must be in accordance with the

B149.1 Installation Code.

• Where required by the authority having jurisdiction, this installation must conform to the

Standard for

Controls and Safety Devices for Automatically Fired Boilers

(ANSI/ASME CSD-1).

2. Read Section VII to verify that the maximum combustion air and exhaust pipe lengths will not be exceeded

in the planned installation. Also verify that the vent terminal can be located in accordance with Section VII.

3. Make sure that the boiler is correctly sized:

• For heating systems employing convection radiation (baseboard or radiators), use an industry

accepted sizing method such as the

I=B=R

Guide RHH published by the Air-Conditioning, Heating and

Refrigeration Institute (AHRI).

III. Before Installing

II. Specifications

(continued)

Table 2.4: Vent Lengths

Model

Size

Nominal

Vent/Intake

Size (in.)

Min. Vent

Length (in.)

Max Vent

Length (ft.)

Approx.

Derate at Max

Vent (%)

135

3

12

135

7

150

3

52

135

7

180

3

52

135

9

Summary of Contents for K2WTC-135

Page 81: ...81 107774 02 4 18 X Domestic Hot Water Piping continued Figure 10 1 Domestic Hot Water Piping...

Page 89: ...89 107774 02 4 18 XI Wiring continued...

Page 90: ...90 107774 02 4 18 Figure 11 8 Internal Wiring Connections Diagram XI Wiring continued...

Page 101: ...101 107774 02 4 18 Lighting and Operating Instructions XII Start Up and Checkout continued...

Page 142: ...142 107774 02 4 18 XVI Repair Parts continued...

Page 145: ...145 107774 02 4 18 XVI Repair Parts continued...

Page 148: ...148 107774 02 4 18 XVI Repair Parts continued...

Page 150: ...150 107774 02 4 18 XVI Repair Parts continued...

Page 152: ...152 107774 02 4 18 XVI Repair Parts continued 120 121 122 123 124 125 126 127...

Page 159: ...159 107774 02 4 18 SERVICE RECORD DATE SERVICE PERFORMED...