Care and Maintenance

10

________________________________________________________________________________________

_______________________________________

10

-

2

10.2 Maintenance chart

In single-shift operation, the operating hours correspond to a certain lubrication

cycle.

2000 hrs ----------

Every year

1000 hrs ----------

Every six months

160

hrs ----------

Every month

40

hrs ----------

Every week

8

hrs ----------

Every day

Item

Maintenance

point

Interval

Maintenance

Work

Lubricant

Remarks

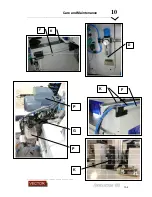

A

Glue System

8 hrs

Clean glue nozzle

face as often as

required but as a

minimum, at the

end of every day.

Clean around

cartridge.

Keeping the glue

system clean is critical

to good operation of

the machine

B

Air motor

8 hrs

Remove air

connection and 1

drop of oil into air

fitting

Light air oil.

C

Linear bearings

trimmer unit and

spline

8 hrs

Drip of light oil on

rails and spline

daily

Trimmer unit should

move vertically easily

D

Air service

Unit

8 hrs

Check for any

condensate.

Drain if necessary.

Ensure automatic

drain is working

correctly

Ensure air supply to

machine is clean and

dry as air drier will not

capture excessive

water and particulate.

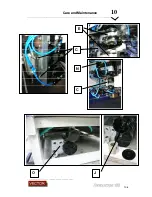

E

Trimmer bearings 320 hrs

Check for noisy

bearings. Replace

as necessary

Damaged bearings

can cause premature

and motor failure!

F

Axis belt tension

160 hrs

Check belts for

tension. Tighten

as necessary

Belts should not be

loose but similarly not

rigid.

G

Chains

160 hrs

Check tension

Lubricate lightly

Castrol

Optimol KL23

or equivalent

I

Dosing Bar

40 hrs

Put a drop of light

oil on top of the

dosing bar

The oil will travel

down the bar

lubricating it’s

movement.

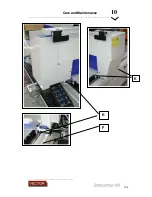

J

Vacuum Pump

40 hrs

Check oil level and

clear filter

Castrol Aircol

PD100

Shell Corena

P100

Top up as necessary

Summary of Contents for Revolution 180

Page 1: ...Operating Manual...