Run

9

________________________________________________________________________________________

_______________________________________

9

-

52

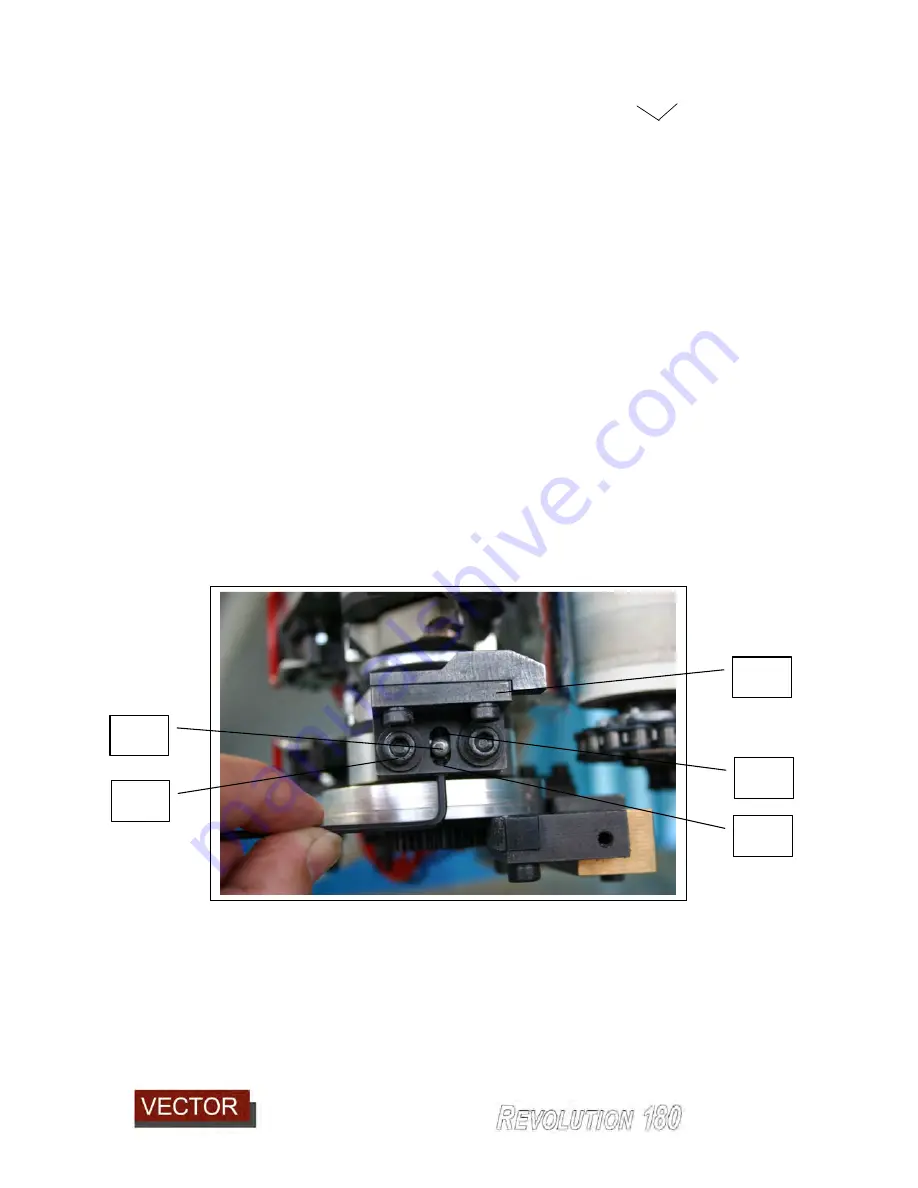

There are 2 locking screws (990) on each block, one fixed pin (992) and an upper (991)

and lower (993) adjusting screw. The shoe is restrained from tilting by a machined tongue

and groove arrangement on their mating faces.

Firstly release the locking screws (990) and then finger tighten them so they provide some

resistance to movement.

Now release the set screw which is resisting movement in the direction which you wish to

move the shoe. For example, if you wish to move the top shoe upward, release the screw

(993) by the amount you wish to move the shoe.

These set screws are M5 x 0.8mm pitch. Thus one full turn amounts to 0.8mm. A ¼ turn

amounts to 0.2mm.

Now tighten the top set screw (991) which will pull the vertical shoe upward until the lower

set screw (993) makes contact again with the fixed pin (992).

Lock the screws (990) on the shoe.

For the lower cutter block the same principal applies although the directions are

reversed.

For example to raise the tracer shoe (exposing less cutter) so that the cutter removes less

material, then release screw (991) the desired amount and pull the shoe up with screw

(993). Re-lock locking screws (990) as per procedure for top cutter block.

When you have completed reading the manual and are ready to run, it is possible to

perform a single panel test to set the trimmers.

It may be convenient to bring the trimmers together when making adjustments. This may

give better access to the adjusting screws and also allow a measuring calliper to measure

the spacing between the tracer shoes for reference. From this it is possible to measure

the adjustment changes made.

930

990

992

993

991

Summary of Contents for Revolution 180

Page 1: ...Operating Manual...