TCI-W11-U, TCI-W22-U Universal Controller

I

NPUT

C

ONFIGURATION

Doc: 70-00-0140C, V2.0-20220523

© Vector Controls LLC, USA

Page 11-24

Subject to alteration

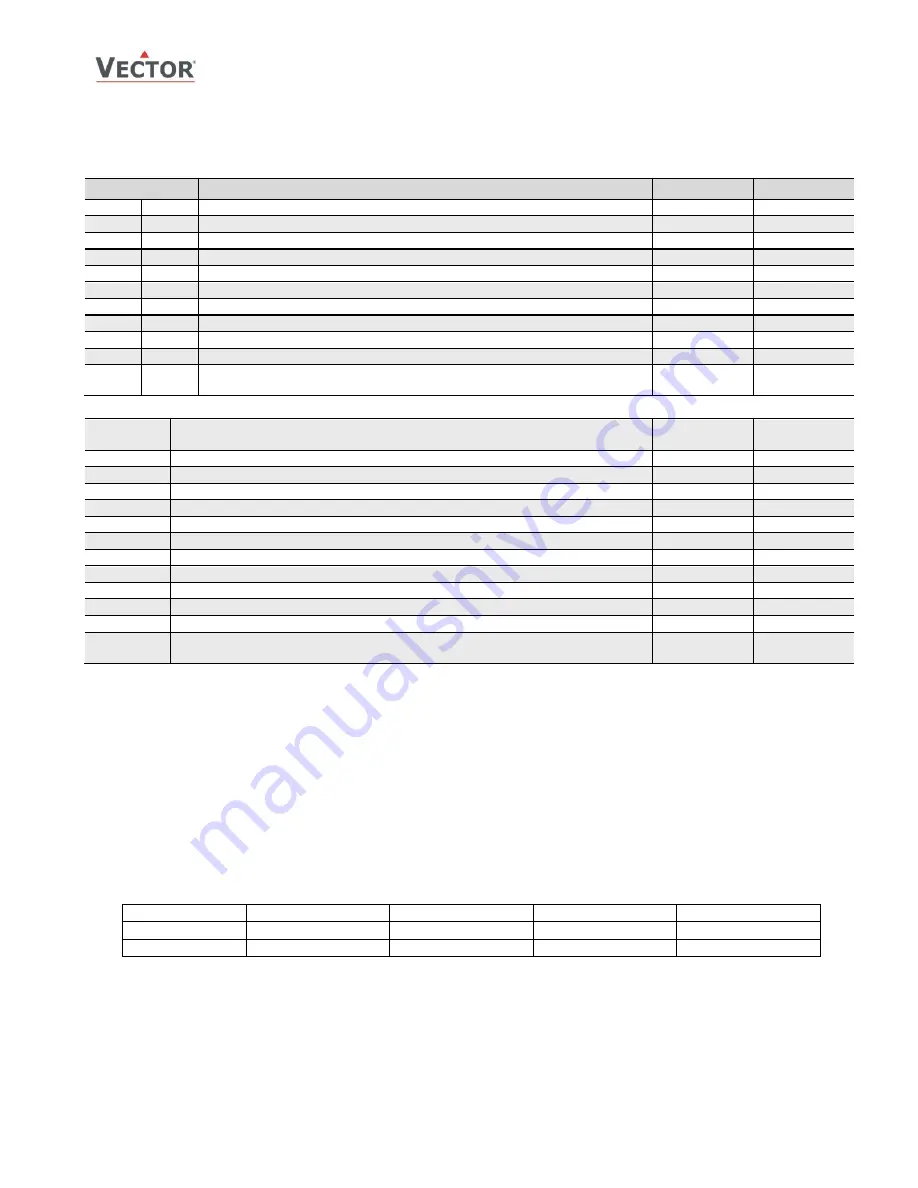

Control configuration (Password 241)

Input configuration

Internal inputs 1T temperature and 1H humidity (with added AES3-HT-A2, -A3 or -A5 element)

Parameter

Description

Range

Default

1T 00

1H 00 Enable internal sensor

OFF/ON

ON

1T 01

1H 01 Display minimum value

-50

–

205

0

1T 02

1H 02 Display maximum value

-50

–

205

100

1T 03

1H 03 Sensor sampling rate (control speed decrease as rate increases)

0

–

100

10

1T 04

1H 04 Sensor calibration

per input

0

1T 05

1H 05 Alarm 1 (1T), Alarm 3 (1H) low limit

OFF/ON

OFF

1T 06

1H 06 Alarm 1 (1T), Alarm 3 (1H) low limit values

-40

–

215°C

5°C/5%

1T 07

1H 07 Alarm 2 (1T), Alarm 4 (1H) high limit

OFF/ON

OFF

1T 08

1H 08 Alarm 2 (1T), Alarm 4 (1H) high limit values

-40

–

215°C

50°C / 95%

1T 09

1H 09 Hysteresis Alarm 1, 2, 3, 4

0

–

100°

5°C/5%

1T 10

1H 10 Calculate a range of inputs (0= not active):

1= average, 2= minimum, 3= maximum, 4= differential

0

–

3

0

Universal inputs 1U = UI1, 2U = UI2 (TCI-W22-U only)

1U 00

Signal type (0= not active):

1= 0-10V or 0-20mA, 2= 2-10V or 4-20mA, 3= passive temperature

0

–

3

1

1U 01

Display minimum value

-50

–

205

0

1U 02

Display maximum value

-50

–

205

100

1U 03

Analog input display range: 0= x 0.1, 1= x 1, 2= x 10, 3 = x 100

0

–

3

1

1U 04

Analog input unit of measure: 0= no unit, 1= %, 2= °C /°F, 3= Pa

0

–

3

2

1U 05

Sensor sampling rate (control speed decrease as rate increases)

0

–

100

10

1U 06

Sensor calibration

Per input

0

1U 07

Alarm 5 (1U), Alarm 7 (2U) low limit

OFF/ON

OFF

1U 08

Alarm 5 (1U), Alarm 7 (2U) low limit value

-40

–

215°C

5°C (41°F)

1U 09

Alarm 6 (1U), Alarm 8 (2U) high limit

OFF/ON

OFF

1U 10

Alarm 6 (1U), Alarm 8 (2U) high limit value

-40

–

215°C

50°C (122°F)

1U 11

Hysteresis alarm 5 and 6 (1U), alarm 7 and 8 (2U)

0

–

100°

5°C (10°F)

1U 12

Calculate a range of inputs (0=not active):

1= average, 2= minimum, 3= maximum, 4= differential

0

–

4

0

➔

Set jumpers on the back of the controller: 0

–

10VDC (default), 0

–

20mA, or RT/DI (passive temperature or binary)

➔

Further define analog inputs with U00

➔

Match sensor range to input display. With a differential pressure transmitter having 0

–

200 Pa measuring range set UO1

display minimum to 0 and U02 display maximum to 200. The allowable range value of -50

–

205 may be adjusted with

multipliers inU03. The largest displayable values are -990

–

9999. Limiting range increases resolution. Applies to analog as

well as passive temperature inputs.

➔

For binary input (open/close contact) set the jumper to RT/DI and parameter U00 to an analog input. An open contact

reads as a high value (100%), a closed contact as a low value (0%).

➔

Enable / Disable an alarm. Setting the alarm enable to OFF will prevent the alarm from being displayed on screen. It may

never the less be used to control an output by setting the appropriate output alarm flags. This way, an alarm limit may be

used as interlock.

➔

Specify the input value that triggers an alarm. Hysteresis is the difference between alarm level input and value required

to turn the alarm off. An alarm is displayed as text if enabled (see table). Alarm text can be set to blink continuously until

acknowledged by pressing the OPTION button or only while the alarm conditions are active (see user parameter UP15).

➔

Calculate mathematical functions over multiple inputs for loop control or display with xU12. In order to calculate average,

minimum or maximum between several inputs, make sure all the inputs are of identical type and range and then activate

the same function on xU12 on all the selected inputs. The largest input of the group selected will carry the calculated

value. For example: When average is activated on 2U12 and 1U12 = 1, the average is carried on UI2.UI2 may now be

used as input for control loops and it will show the average value of UI1 and UI2 combined. It is possible to use different

functions on different inputs. For example: minimum of UI1 and UI3 and maximum of UI2 and UI4.

➔

The differential function may only be calculated on subsequent inputs. Such as UI2-UI1. The function must only be

activated on the minuend (UI2 in this example). The displayed value of the minuend will change into the difference: UI2

in

–

UI1 = UI2 out. It is possible to have multiple differentials on one controller. It is not possible to reverse the

subtraction to UI1-UI2.

Input

1T

1H

1U

2U

Low limit

ALA1

ALA3

ALA5

ALA7

High limit

ALA2

ALA4

ALA6

ALA8