M3000

Installation Manual

132

•

If the LED is yellow, the controller firmware does not match with the latest firmware on the Server

computer.

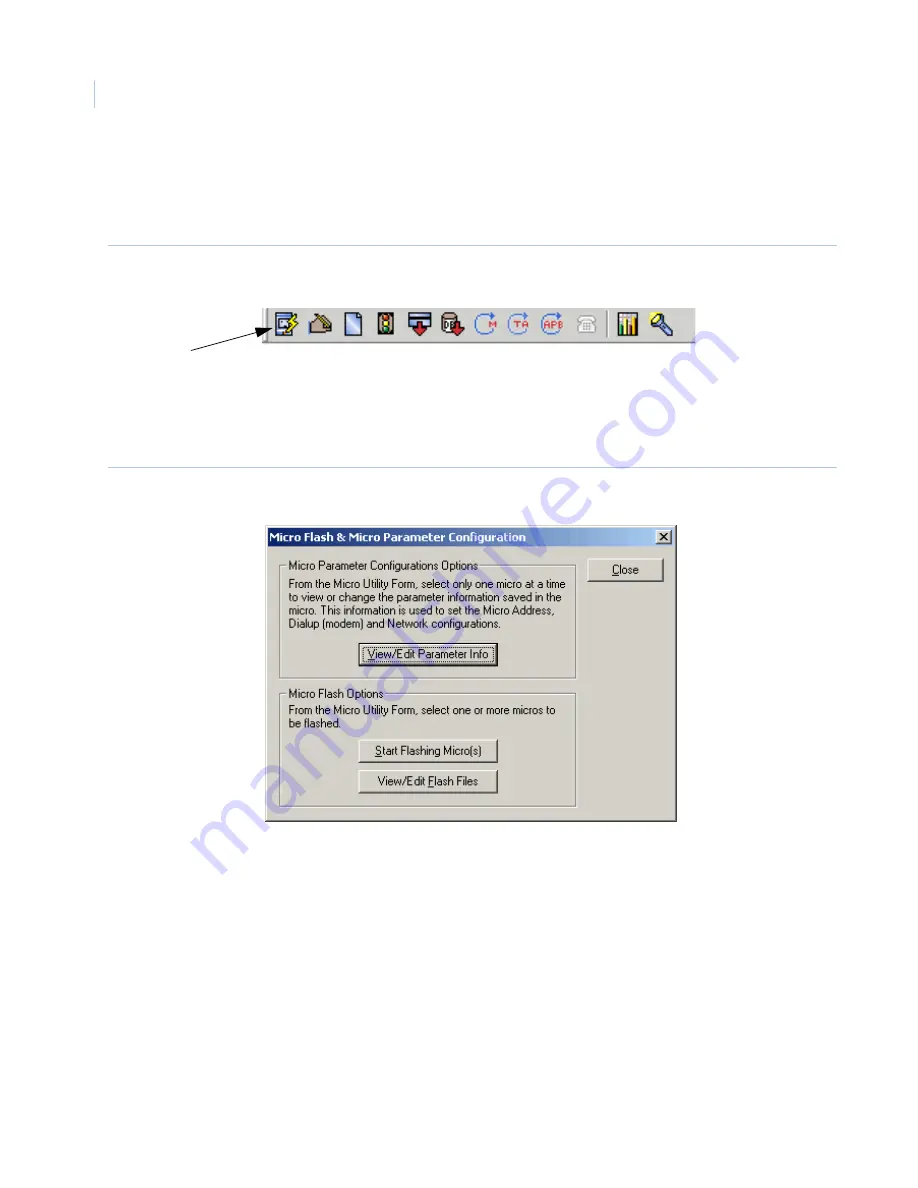

5. Click

Flash

from the

Micro Utility Form

toolbar.

Figure 56.Micro Utility Form toolbar

Result:

The

Micro Flash & Micro Parameter Configuration

window displays. This window is

available only if the controller is online.

Figure 57.Micro Flash & Micro Parameter Configuration window

6. Click

Start Flashing Micro(s)

to immediately download the appropriate firmware to the controller.

Result:

A dialog box will display asking you to verify your request.

To select a specific flash file, click

View/Edit Flash Files

. This option is primarily used by Technical

Support personnel when it is necessary to selectively flash an older version of firmware on a controller.

Flash Icon

Summary of Contents for M3000

Page 1: ...M3000 Installation Manual P N 460630001H 15JUNE11 ...

Page 10: ...M3000 Installation Manual x ...

Page 39: ...Chapter 3 Power Communications board 29 Figure 11 Wiring modem to M3000 M 5 or serial printer ...

Page 47: ...Chapter 4 PXNplus CPU board 37 Board layout Figure 16 PXNplus CPU board layout ...

Page 58: ...M3000 Installation Manual 48 Board layout Figure 17 2RP reader board layout ...

Page 68: ...M3000 Installation Manual 58 Figure 24 Wiring 2RP door strike external relay ...

Page 72: ...M3000 Installation Manual 62 Board layout Figure 27 2SRP supervised reader board layout ...

Page 82: ...M3000 Installation Manual 72 Figure 19 Wiring 2SRP door alarm contact and exit request ...

Page 84: ...M3000 Installation Manual 74 Figure 21 Wiring 2SRP door strike external relay ...

Page 89: ...Chapter 5 Reader processing boards 79 Board layout Figure 24 8RP reader board layout ...

Page 92: ...M3000 Installation Manual 82 Figure 26 Wiring 8RP to F 2F or Supervised F 2F Readers ...

Page 94: ...M3000 Installation Manual 84 ...

Page 97: ...Chapter 6 Optional DI and DO boards 87 Figure 31 20DI board layout ...

Page 99: ...Chapter 6 Optional DI and DO boards 89 Figure 32 Wiring DI point ...

Page 101: ...Chapter 6 Optional DI and DO boards 91 Figure 33 16DO board layout ...

Page 102: ...M3000 Installation Manual 92 Figure 34 16DOR board layout ...

Page 104: ...M3000 Installation Manual 94 Figure 36 Wiring output device to 16DOR board ...

Page 152: ...M3000 Installation Manual 142 ...

Page 156: ...M5 controller Installation Manual 146 Figure 76 Installing ferrite ...

Page 160: ...M5 controller Installation Manual 150 ...

Page 172: ...M3000 Installation Manual 162 ...