035-19624-001 Rev. A (0104)

20

Unitary Products Group

ADJUSTMENT OF MANIFOLD GAS PRESSURE

Manifold gas pressure may be measured by two different procedures. It

may be measured with the burner box cover in place or it may be mea-

sured with the burner box cover removed. Follow the appropriate sec-

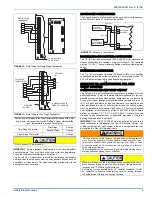

tion in the instructions below. Refer to Figure 27 for a drawing of the

locations of the pressure ports on the gas valve.

Turn gas off at the ball valve or gas cock on gas supply line

before the gas valve. Find the pressure ports on the gas

valve marked Out Pressure Tap and Inlet Pressure Tap.

1.

The manifold pressure must be taken at the port marked OUT

Pressure Tap.

2.

The gas line pressure must be taken at the port marked Inlet Pres-

sure Tap.

Using a screw driver, remove the cap that covers the manifold pressure

set screw.

Read the inlet gas pressure using either of the two meth-

ods below.

Reading the gas pressure with the burner box cover in place -

Dis-

connect the pressure reference hose from the right side of the burner

box. Using a tee fitting and a short piece of hose, connect the negative

side of the manometer to the burner box. Connect the possitive side of

the monometer to the adapter previously installed in the Out Pressure

Tap on the gas valve. Refer to Figure 27 for connection details.

Reading the gas pressure with the burner box cover removed -

Remove the screws securing the burner box front cover plate. Remove

the cover. The gasket may stick in place. Connect the positive side of

the manometer to the adapter previously installed in the Out pressure

Tap on the gas valve. Do not connect any tubing to the negative side of

the monometer, as it will reference atmospheric pressure. Refer to Fig-

ure 27 for connection details.

IMPORTANT:

The cap for the pressure regulator must be removed

entirely to gain access to the adjustment screw. Loosening or tightening

the cap does not adjust the flow of gas.

1.

The regulated outlet pressures, both low and high, have been cali-

brated at the factory. Additional pressure adjustment should not be

necessary. If adjustment is necessary, set to the following specifi-

cations. After adjustment, check for gas leakage.

High Outlet Pressure Adjustment

1.

Turn off all electrical power to the system at main fuse or circuit

breaker.

2.

Attach a manometer to the outlet pressure tap of the valve.

3.

Turn on power and energize main and redundant (P.M.) solenoids

as well as the HI terminal.

4.

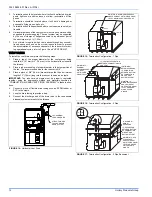

Remove high adjustment seal screw to expose the 3/32”. See Fig-

ure 26.

5.

To increase outlet pressure, turn the 3/32” set screw clockwise . To

decrease outlet pressure, turn the set screw counterclockwise.

Adjust regulator until pressure shown on manometer matches the

pressure specified on the appliance rating plate.

6.

Replace low adjustment seal screw and tighten securely. Cycle the

valve several times to verify regulator setting.

7.

Remove manometer and replace the outlet pressure tap plug.

Low Outlet Pressure Adjustment

1.

Turn off all electrical power to the system at main fuse or circuit

breaker.

2.

Attach a manometer to the outlet pressure tap of the valve.

3.

Turn on power and energize main and redundant (P.M.) solenoids.

Do not energize HI terminal.

4.

Remove low adjustment seal screw. See Figure 26.

5.

To increase outlet pressure, turn the 3/32” set screw below the low

adjustment seal screw clockwise. To decrease outlet pressure,

turn the set screw counterclockwise. Adjust regulator until pres-

sure shown on manometer matches the pressure specified on the

appliance rating plate.

6.

Replace high adjustment seal screw and tighten securely. Cycle

the valve two and three times to verify regulator setting.

7.

Remove manometer and replace the outlet pressure tap.

IMPORTANT:

If gas valve regulator is turned in (clockwise), manifold

pressure is increased. If screw is turned out (counterclockwise), mani-

fold pressure will decrease.

8.

After the manifold pressure has been adjusted, re-calculate the

furnace input to make sure you have not exceeded the specified

input on the rating plate. Refer to “CALCULATING THE FURNACE

INPUT (NATURAL GAS)”.

9.

Once the correct BTU (kW) input has been established, turn the

gas valve to OFF and turn the electrical supply switch to OFF; then

remove the flexible tubing and fittings from the gas valve pressure

tap and re-install the plug in the Out Pressure Port using a com-

pound (on the threads) resistant to the action of LP gases.

Replace the burner box front cover (if it was removed) and replace

the pressure reference hose.

10. Turn the electrical and gas supplies back on, and with the burners

in operation, check for gas leakage around the gas valve pressure

port for leakage using an approved non-corrosive gas leak detec-

tion fluid, or other non-flammable leak detection methods.

TABLE 14:

Nominal Manifold Pressure

NOMINAL MANIFOLD PRESSURE

Natural Gas (High Fire)

3.5" w.c. (0.87 kPa)

Natural Gas (Low Fire)

1.6" w.c. (0.40 kPa)

Propane (LP) Gas (High Fire)

10.0" w.c. (2.488 kPa)

Propane (LP) Gas (Low Fire)

4.0" w.c. (0.99 kPa)

The manifold pressure must be checked with the screw-off cap for

the gas valve pressure regulator in place. If not, the manifold pres-

sure setting could result in an over-fire condition. A high manifold

pressure will cause an over-fire condition, which could cause pre-

mature heat exchanger failure. If the manifold pressure is too low,

sooting and eventual clogging of the heat exchanger could occur.

Be sure that gas valve regulator cap is in place and burner box to

gas valve pressure reference hose is connected.