035-19624-001 Rev. A (0104)

Unitary Products Group

21

ADJUSTMENT OF TEMPERATURE RISE

The temperature rise, or temperature difference between the return air

and the heated supply air from the furnace, must be within the range

shown on the furnace rating plate and within the application limitations

as shown in Table 7.

After about 20 minutes of operation, determine the furnace temperature

rise. Take readings of both the return air and the heated air in the ducts,

about six feet (1.83 m) from the furnace where they will not be affected

by radiant heat. Increase the blower speed to decrease the temperature

rise; decrease the blower speed to increase the rise.

DIRECT DRIVE MOTORS

Adjustment of Fan-Off Control Settings

This furnace is equipped with a time-on/time-off heating fan control. The

fan-on is fixed at 30 seconds. The fan-off delay is factory set to 60 sec-

onds; however, it is field-adjustable to 90, 120 or 180 seconds. The fan-

off setting must be long enough to adequately cool the furnace, but not

so long that cold air is blown into the heated space. The continuous fan

speed dip switch (switch 3) on the ignition control has no affect on set-

ting and should be left in the off position, as continuous fan speed is

determined by the variable speed motor program.

Direct Drive Motors (Only Applies to PSC Replacement)

The temperature rise, or temperature difference between the return air

and the heated air from the furnace, must be within the range shown on

the furnace rating plate. Application limitations are shown in Table 7.

After the temperature rise has been determined, the CFM can be calcu-

lated. After about 20 minutes of operation, determine the furnace tem-

perature rise. Take readings of both the return air and the heated air in

the ducts, about six feet from the furnace where they will not be affected

by radiant heat. Increase the blower speed to decrease the temperature

rise; decrease the blower speed to increase the rise. All direct-drive

blowers have multi-speed motors. The blower motor speed taps are

located in the control box in the blower compartment. You may select a

heating speed and a cooling speed. They may be the same speed or a

different speed. To use the same speed tap for heating and cooling, the

heat terminal and cool terminal must be connected using a jumper wire

and connected to the desired motor lead.

Replacement of the Variable Speed Motor with a PSC Direct

Drive Motor

NOTE:

A failed variable speed motor should always be replaced with a

variable speed motor suitable for the furnace model being ser-

viced. However, if one is not available, a 3-speed direct drive

motor may be used in the interim.

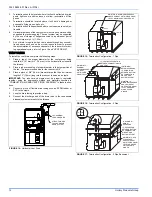

Removal of the Variable Speed Blower Assembly and

Motor

The procedure for removing the direct drive blower assembly is as fol-

lows:

1.

Disconnect the electrical supply to the furnace and remove the

access doors.

2.

Remove blower assembly mounting screws and slide the blower

assembly out of the slots in the deck. If the two shipping screws

were not previously removed, also remove and discard these two

screws located on each front corner of the blower assembly.

3.

Loosen the blower wheel set screw and the motor mount bolt, and

slide the variable speed motor out of the blower housing.

4.

To reassemble, reverse the procedure, restore power to the fur-

nace and verify operation.

Installation PSC Motor

1.

Install the PSC direct drive motor into motor mount.

2.

Slide motor in motor mount insuring there is no interference

between moving and stationary parts. Position wire leads down-

ward. Tighten motor mount band screw to 30 in. lbs.

3.

Center the blower wheel in the blower housing and align the shaft

flat with the blower wheel set screw. Tighten setscrew to 30 in. lbs.

4.

Replace blower assembly and fasten with 5 screws

5.

Strap motor capacitor to electric panel. Refer to Table 15, for

proper capacitor selection.

6.

Fasten electric panel to blower housing.

7.

Remove red wire from Circ. input terminal. Plug jumper wire

(attach to motor power harness) on 120-volt line terminal on igni-

tion control and jumper to Circ. Input. Connect brown door switch

wire to jumper.

8.

Connect white main harness lead to Line neutral.

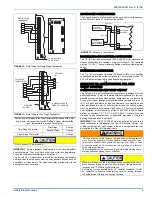

WITH BURNER BOX COVER IN PLACE

WITH BURNER BOX COVER REMOVED

FIGURE 27:

Reading Gas Pressure

6

5

4

3

2

1

0

1

2

3

4

5

6

GAS VALVE

OUTLET

PRESSURE TAP

BURNER BOX PRESSURE

REFERENCE HOSE

BURNER BOX

WITH COVER

TEE

FITTING

U-TUBE

MANOMETER

3.5 IN

WATER COLUMN

GAS PRESSURE

SHOWN

6

5

4

3

2

1

0

1

2

3

4

5

6

GAS VALVE

OUTLET

PRESSURE TAP

BURNER BOX

WITH COVER

REMOVED

BURNER BOX

PRESSURE

REFERENCE HOSE

(NOT USED)

3.5 IN

WATER COLUMN

GAS PRESSURE

SHOWN

U-TUBE

MANOMETER

The temperature rise, or temperature difference between the return

air and the supply (heated) air from the furnace, must be within the

range shown on the furnace rating plate and within the application

limitations shown in Table 7 “ELECTRICAL AND PERFORMANCE

DATA”.

The supply air temperature cannot exceed the “Maximum Supply

Air Temperature” specified in these instructions and on the fur-

nace rating plate. Under NO circumstances can the furnace be

allowed to operate above the Maximum Supply Air Temperature.

Operating the furnace above the Maximum Supply Air Temperature

will cause premature heat exchanger failure, high levels of Carbon

Monoxide, a fire hazard, personal injury, property damage, and/or

death.