035-19624-001 Rev. A (0104)

18

Unitary Products Group

IGNITION SYSTEM SEQUENCE

1.

Turn the gas supply

ON

at external valve. See Figure 7.

2.

Turn the gas valve switch to the

ON

position. See Figure 26.

3.

Set the thermostat above the room temperature to initiate the call

for heat.

4.

The furnace ignition system will start as follows:

a.

The Integrated Ignition Control Board will do a self-diagnostic

test.

b.

It will check all limits and pressure switch(s).

c.

The draft inducer motor will start high speed.

d.

Pressure switch(s) will close

e.

The draft inducer motor will go to low speed.

f.

The hot surface igniter will warm up for 17 seconds.

g.

Gas valve will open low fire for 7 seconds.

h.

Flame rectifaction will prove flame.

i.

Blower motor low heat comes on in 30 seconds.

j.

Thermostat call for W2.

k.

The draft inducer motor will go to high speed.

l.

Pressure switch will close.

m.

Gas valve will open high fire.

n.

Blower motor high heat comes on in 30 seconds.

o.

Thermostat W2 ends, gas valve will go to low fire.

p.

The draft inducer motor will go to low speed.

q.

Blower motor goes to low heat in 30 seconds.

r.

Thermostat ends call for heat.

s.

Draft inducer motor does 15 seconds post purge.

t.

Blower continues for adjusted time delayed.

IMPORTANT:

Burner ignition may not be satisfactory on first startup

due to residual air in the gas line or until gas manifold pressure is

adjusted. The ignition control will make 3 attempts to light before lock-

ing out.

With furnace in operation, check all of the pipe joints, gas valve connec-

tions and manual valve connections for leakage using an approved gas

detector, a non-corrosive leak detection fluid, or other leak detection

methods. Take appropriate steps to stop any leak. If a leak persists,

replace the component.

The furnace and its equipment shutoff valve must be disconnected from

the gas supply piping system during any pressure testing of the system

where test pressures are in excess of 1/2 PSI (3.45 kPa).

CALCULATING THE FURNACE INPUT

(NATURAL GAS)

NOTE:

Front door of burner box must be secured when checking gas

input.

NOTE:

Burner orifices are sized to provide proper input rate using nat

ural gas with a heating value of 1050 BTU/Ft

3

. If the heating

value of your gas is significantly different, it may be necessary to

replace the orifices.

1.

Turn off all other gas appliances connected to the gas meter.

2.

At the gas meter, measure the time (with a stop watch) it takes to

use 2 cubic ft. (0.0566 m

3

.) of gas.

3.

Calculate the furnace input by using one of the following equa-

tions.

In the USA use the following formula to calculate the furnace input.

For natural gas

multiply the heat content of the gas BTU/SCF (or Default 1030 BTU/SCF, times 2 cubic ft. of gas measured at the gas meter, times

a barometric pressure and temperature correction factor of 0.960; times 3600, then divided by the time (In seconds) it took to measure 2 cubic ft. of

gas from the gas meter.

For propane (LP)

gas multiply the heat content of the gas BTU/SCF (or Default 2500 BTU/SCF, times 1 cubic ft. of gas measured at the gas meter,

times a barometric pressure and temperature correction factor of 0.960; times 3600, then divided by the time (In seconds) it took to measure 1 cubic

ft. of gas from the gas meter.

The formula for US input calculation using a cubic foot gas meter:

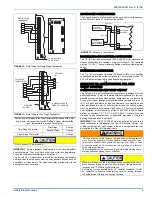

FIGURE 26:

Gas Valve

R

E

P

L

A

C

E

R

E

P

L

A

C

E

SCRE

W

SCRE

W

PM

C

HI

O

F

F

ON

INLET

OUTLET

WRENCH

BOSS

ON / OFF SWITCH

HI ADJUST

LO

ADJUST

LOW FIRE

REGULATOR

ADJUSTMENT

SEAL SCREW

HIGH FIRE

REGULATOR

ADJUSTMENT

SEAL SCREW

BTU/f

3

x 2 cu.ft. x 0.960 x 3600

=

BTUH/H

BTU/f

3

x 2 cu.ft. x 0.960 x 3600

=

BTUH/H

Seconds it took to measure the 2 cu.ft. of gas

Seconds it took to measure the 2 cu.ft. of gas

NATURAL GAS INPUT CALCULATION

PROPANE (LP) GAS INPUT CALCULATION

EXAMPLE:

EXAMPLE:

1030 x 2 x 0.960 x 3600

=

79,997.38

2500 x 1 x 0.960 x 3600

=

80,000.00

90.5

108

Natural Gas

Propane Gas

BTU/SCF 1030

BTU/SCF 2500