035-19624-001 Rev. A (0104)

22

Unitary Products Group

9.

Connect motor leads to cool, heat lo and heat high per electrical

wire diagram table in the Installation manual.

10. Connect brown capacitor leads from motor to capacitor and cover

terminals with boot supplied.

POWER SUPPLY POLARITY - Ignition Control:

If the power supply

polarity is reversed, the following unit operation will occur. On a call for

heat, the inducer will run, the HSI will glow and the gas valve will ener-

gize and the burners will ignite. The burners will immediately extinguish

and the unit will recycle. This will occur 3 times and then the unit will

lockout. A "7" flash code will be displayed. This code means the flame

could not be established. This occurs because the control cannot sense

flame with the power supply polarity reversed.

VARIABLE SPEED MOTORS

The variable speed motor CFM / Timer Control Board must be config-

ured so the blower will provide a sufficient airflow so that the furnace

operates with in the temperature rise range on the rating plate and

within the application limitations shown in Table 7 in these Instructions.

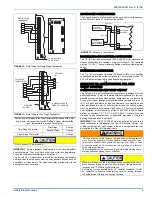

ADJUSTMENT OF FAN CONTROL SETTINGS

This furnace is equipped with a time-on/time-off heating fan control. The

fan on delay is fixed at 30 seconds. The fan off delay has 4 settings (60,

90, 120 and 180 seconds). The fan off delay is factory set to 120 sec-

onds. The fan-off setting must be long enough to adequately cool the

furnace, but not so long that cold air is blown into the heated space. The

fan-off timing may be adjusted by positioning the jumper on two of the

four pins as shown in Figure 28.

Heating Indoor Fan Off Delay

The dip switches are located above the thermostat terminals. Refer to

Figure 28 for the dip switch settings to obtain the desired fan OFF delay.

The blower off delay must be long enough to adequately cool the fur-

nace, but not so long that cold air is blown into the living space.

The blower on delay is fixed at 30 seconds and can not be adjusted.

The continuous fan speed dip switch (switch # 3 on the Integrated Con-

trol) does not function on variable speed models. Dip switch # 3 should

be left in the off position.

Heating and Cooling Airflow

The heating and the cooling airflows are preset at the factory. The heat-

ing airflow is set to the maximum CFM. The cooling airflow is set to pro-

vide 90 percent of the maximum CFM. The heating and cooling airflows

must be field adjusted to match the HVAC system at installation.

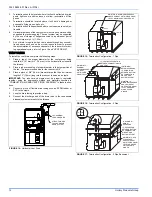

CFM / Timer Board: Delay Taps Selection

Position "A" is the factory setting and is used for test purposes. The

blower will operate at 100% of the cooling airflow for 60 seconds.

Move the jumper to Position "B" for a two-stage condenser. This results

in 82% of the cooling airflow with a 45 second off delay.

Move the jumper to position "C" for a system with a TXV or solenoid

valve. This results in 75% of the cooling airflow with a 45 second off

delay.

Move the jumper to position "D" for a system without a TXV or solenoid

valve. This results in 82% of the cooling air flow with a 60 second off

delay.

NOTE:

The blower will have a 15 second coast to stop in all of the

above positions.

Continuous Blower

The Integrated (Ignition) Control does not control the operation of the

blower when it is run in the continuous mode. The CFM / timer Board

controls the blower in the continuous mode through the "G" terminal on

the thermostat. When the thermostat fan-switch is set to the ON posi-

tion a circuit is completed between "R" and "G". This will cause the

blower to operate continuously at 63% of the high cool speed.

If more airflow is desired, you must locate the green wire labeled "G

Cool Speed" which is located in the wire bundle near the Integrated

(Ignition) Control. After the wire has been located, connect it to the "G"

terminal on the Integrated (Ignition) Control. This will cause the blower

to operate at the HIGH COOL speed. Dip switch 3 must be in the OFF

position.

TABLE 15:

Replacement PSC Motor

Low Fire

Heating Input

Low Fire

Heating Output

High Fire

Heating Input

High Fire

Heating Output

Furnace

Airflow

Motor Part

Number

Motor

Horsepower

Capacitor

Part Number

Capacitor

Rating

BTU/H

kW

BTU/H

kW

BTU/H

kW

BTU/H

kW

CFM cm/m

39,000

11.43

36,000

10.55

60,000

17.58

55,000

16.12 1200 33.98 024-23271-000

1/2

024-20045-000

7.5 µf

52,000

15.24

48,000

14.07

80,000

23.45

75,000

21.98 1600 45.31 024-26002-000

3/4

024-20046-000

10.0 µf

65,000

19.05

60,000

17.58

100,000

29.31

95,000

27.84 2000 56.63 024-23288-001

1

024-20446-000

15.0 µf

78,000

22.86

72,000

21.10

120,000

35.17

112,000 32.82 2000 56.63 024-23238-001

1

024-20446-000

15.0 µf

Do not energize more than one motor speed at a time or damage to

the motor will result.

FIGURE 28:

White Rodgers Intergrated Control

INDOOR FAN OFF

DELAY DIP SWITCHES

FIGURE 29:

CFM / Timer Board

BLOWER MOTOR

CONNECTIONS

TWO STAGE VARIABLE SPEED THERMOSTAT CONNECTIONS ONLY

HIGH HEA

T

MANUAL TIME

R