035-19624-001 Rev. A (0104)

16

Unitary Products Group

Specially Engineered Installations

The above requirements shall be permitted to be waived where special

engineering, approved by the authority having jurisdiction, provides an

adequate supply of air for combustion, ventilation and dilution of flue

gases.

SECTION VII: CONDENSATE DRAIN

INTERNAL CONDENSATE DRAIN PIPING

The condensate drain connection is provided in the furnace for field

installation. It consists of a formed hose with a 1/2” (12.7 mm) NPT

male connection. A 1/2” (12.7 mm) FM x 3/4” (19 mm) PVC slip cou-

pling is provided.

This drain hose may be installed to allow left or right side condensate

drain connection, refer to Figure 24. Cut the hose to allow for proper fit

for left or right exit.

To install the drain hose assembly, remove the 7/8” (22 mm) knockout in

the side panel. Remove the conduit nut from the 1/2” (12.7 mm) male

fitting. Push the male fitting through the hole and reinstall the nut. The

use of the 3/4” (19 mm) PVC coupling is optional.

EXTERNAL CONDENSATE DRAIN PIPNG

The following steps apply to all models:

1.

Condensate must be disposed of properly. Follow local plumbing

or wastewater codes.

2.

The condensate piping may be connected in common with the

condensate drain from the air conditioning coil if:

a.

The air conditioning condensate drain line is trapped

upstream of the tie-in.

b.

The combined drains are constructed of the same material.

c.

If allowed by local codes.

d.

Follow the instructions provided with air conditioning coil con-

densate drain trap.

3.

It is recommended that either 1/2” or 3/4” PVC or equivalent pipe

be field installed as drain pipe from the furnace to the floor drain or

condensate pump.

4.

All pipe joints must be cleaned, de-burred and cemented using

PVC primer and cement.

5.

The drain line must maintain a 1/4” per foot (0.635 cm per meter)

slope to the floor drain or condensate pump.

6.

Where required, a field-supplied neutralizer can be installed in the

drain line, external to the furnace.

CONDENSATE DRAIN TERMINATION

DO NOT terminate condensate drain in a chimney, or where the drain

line may freeze. The line must terminate at an inside drain to prevent

freezing of the condensate and possible property damage.

DO NOT trap the drain line at any other location than at the condensate

drain trap supplied with the furnace.

A condensate sump pump MUST be used if required by local codes, or

if no indoor floor drain is available. The condensate sump pump must

be approved for use with acidic condensate.

CONDENSATE DRAIN TRAP AND DRAIN FREEZE

PROTECTION

Special precautions MUST be made if installing furnace in an area

which may drop below freezing. This can cause improper operation or

damage to the equipment. If the furnace is installed in an area that has

the potential of freezing, the drain line and the drain trap must be pro-

tected. Use a 3 to 6 watt per foot (0.003 to 0.006 kW per meter) at 115

vac, 40º f self-regulating, shielded and waterproof heat tape. Wrap the

drain trap and the drain line with the heat tape and secure with ties. Fol-

low the heat tape manufacturer's recommendations.

CONDENSATE DRAIN PRE-OPERATION

PROCEDURE

The condensate trap must be filled with water before putting the furnace

into operation. Perform the following procedures only after the conden-

sate trap has been properly piped to a drain connection using the pro-

cedure in this instruction.

The recommended procedure is as follows:

1.

Disconnect the condensate drain hose from the induced draft

blower discharge.

2.

Elevate this hose and fill with water using a funnel.

3.

Replace the condensate drain hose and clamps.

If this procedure is not followed, the unit may not properly drain on initial

start up.

SECTION VIII: SAFETY CONTROLS

CONTROL CIRCUIT FUSE

A 3-amp fuse is provided on the control circuit board to protect the 24-

volt transformer from overload caused by control circuit wiring errors.

This is an ATO 3, automotive type fuse and is located on the control

board.

BLOWER DOOR SAFETY SWITCH

This unit is equipped with an electrical interlock switch mounted in the

blower compartment. This switch interrupts all power at the unit when

the panel covering the blower compartment is removed.

Electrical supply to this unit is dependent upon the panel that covers the

blower compartment being in place and properly positioned.

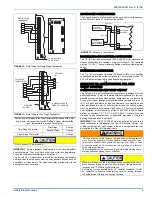

FIGURE 23:

Attic and Crawl Space Combustion Air Termination

Be sure to instruct the owner not to block this intake pipe.

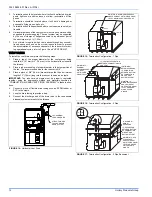

FIGURE 24:

Condensate Piping

12” MINIMUM BETWEEN

BOTTOM OF BELOW AND

ANY MATERIAL

12”

MIN.

LH DRAIN

RH DRAIN

Main power to the unit must still be interrupted at the main power

disconnect switch before any service or repair work is to be done to

the unit. Do not rely upon the interlock switch as a main power dis-

connect.

Blower and burner must never be operated without the blower

panel in place.