Source NDP Cleaning

4–2

4326

6295–002

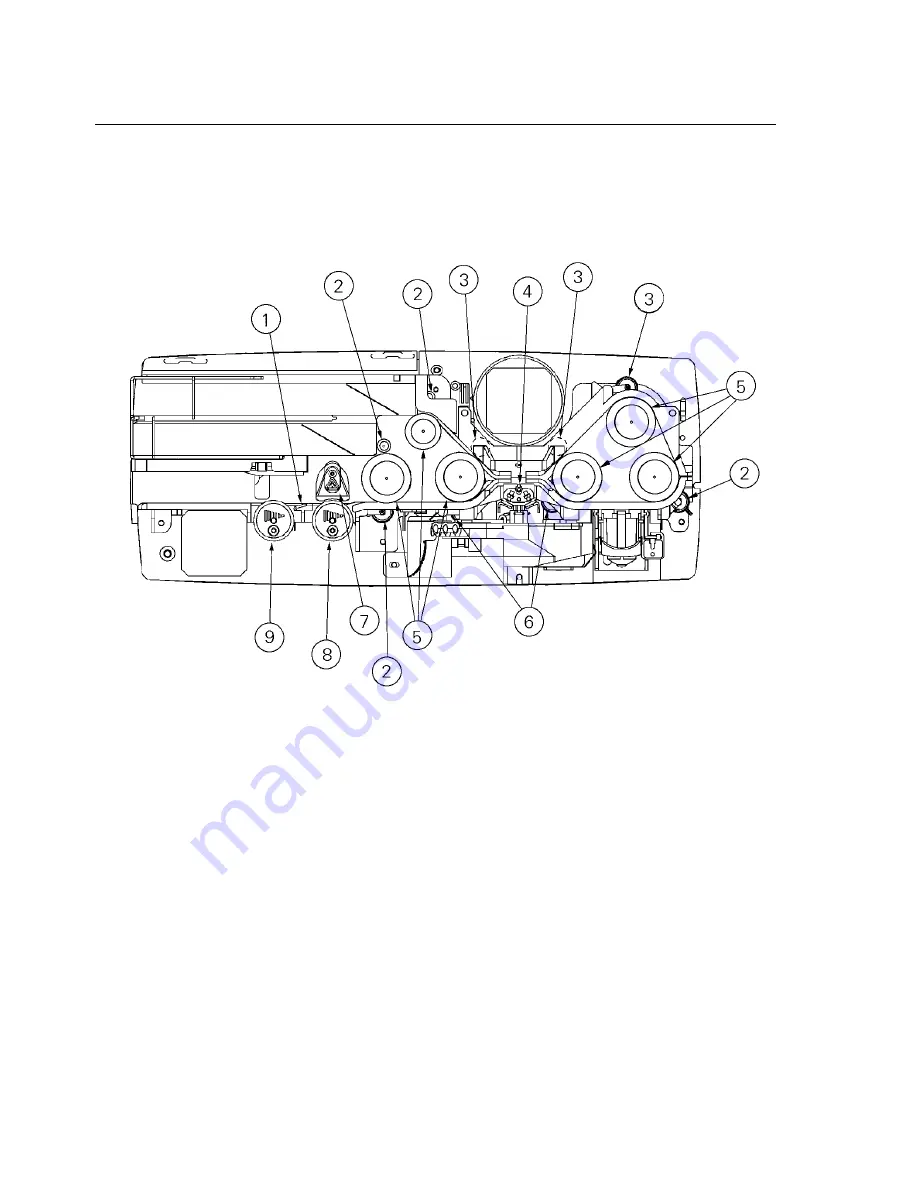

Location of Components for Cleaning

Figure 4-1 shows the location of components for cleaning.

Legend

1

Reflective sensor

6

Idler roller (not accessible)

2

Idler roller in track (4 sets of rollers)

7

Separator

3

Idler roller in removable track wall

8

Feed roller

4 Image glass

9

Nudge roller

5

Drive roller (6 rollers)

Figure 4–1. Location of Components for Cleaning

Summary of Contents for e-action Source NDP

Page 7: ...Contents vi 4326 6295 002 ...

Page 25: ...Source NDP Installation 2 14 4326 6295 002 Figure 2 15 Packing the Source NDP for Shipping ...

Page 43: ...Source NDP Operation and Document Processing 3 18 4326 6295 002 ...

Page 79: ...Removal and Replacement of Source NDP Components 5 26 4326 6295 002 ...

Page 91: ...Recovery from Problem Conditions 6 12 4326 6295 002 ...

Page 95: ...Source NDP Specifications A 4 4326 6295 002 ...

Page 97: ...Document Specifications B 2 4326 6295 002 ...

Page 109: ...Index Index 4 4326 6295 002 ...

Page 110: ... ...