pg. 18

CLEANING & MAINTENANCE

Following these simple steps daily will ensure that your printer lasts longer and help you

achieve optimal performance with little to any down time from your UNINET

™

DTF 100 printer.

Daily to Do

Whether you will be printing for the day or not, it is important to power the machine on and

perform both a head cleaning and a nozzle check to ensure all the printhead is clean and clear of

any build-up or debris. It is strongly recommended to print on a daily basis, even if professional

printing is not required, in order to keep the ink circulating/flowing. Otherwise, ink will stagnate,

separate and possibly get dry/clog into the ink circuitry, damaging consumable parts.

There are two ways you can perform a head cleaning on the UNINET

™

DTF 100:

1.

With the printer powered on and sitting idle, press and hold the Ink Drop button until you

hear the printer begin to make sounds. This initiates a head cleaning without using any

software. This can take several minutes to complete.

2.

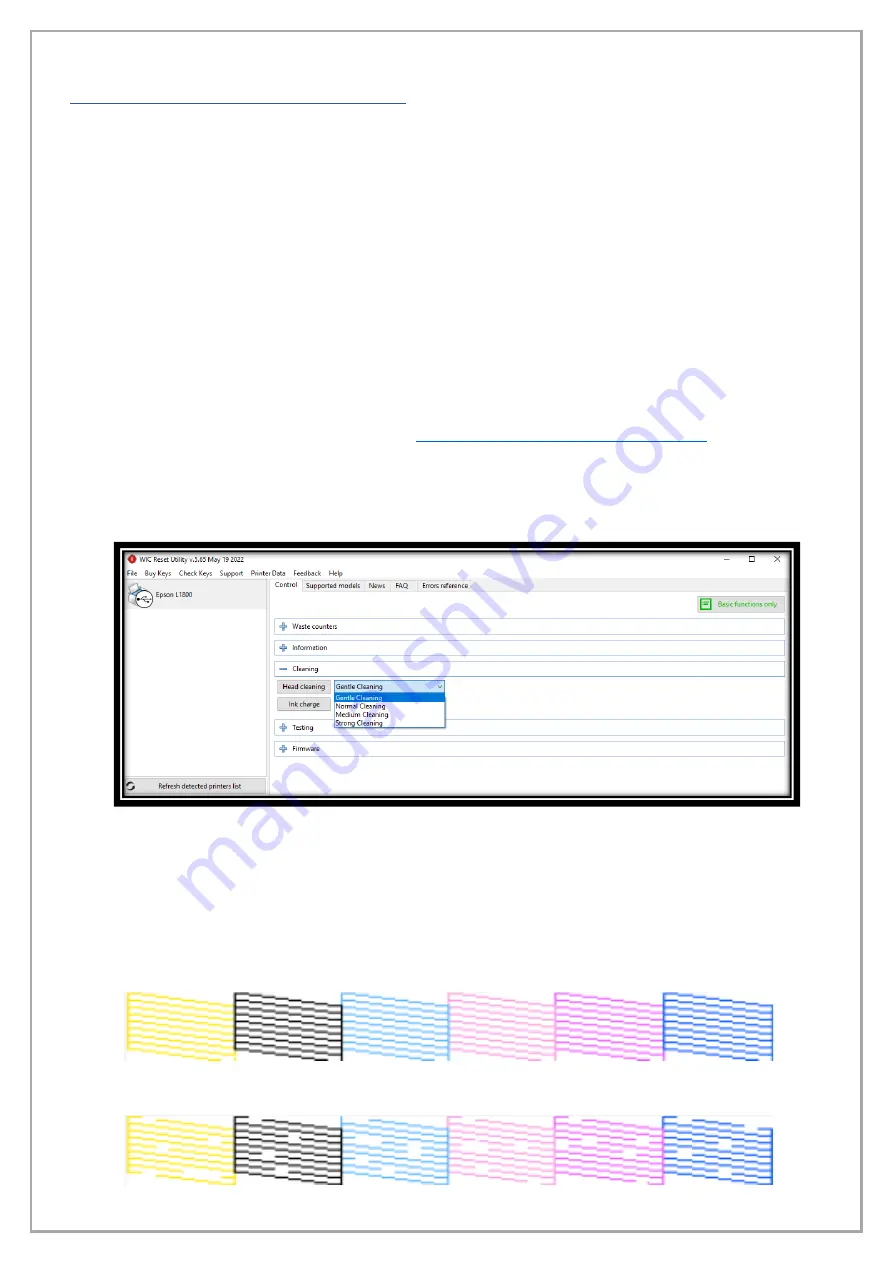

Using the WIC Reset Utility software:

https://wic-reset.com/files/wicreset.zip

Select your UNINET

™

DTF 100 printer from the list on the left-hand side. Expand the Cleaning

dropdown list, this will present you with a couple different functions to perform. For this

situation, select either the Medium or Normal option from the dropdown list next to Head

Cleaning.

Once the printer has completed its head cleaning, it is very important to perform a nozzle check to

ensure the printhead is in a healthy state. The goal is for your printhead to have little to no breaks,

separations or clogs in any of the channels, if there are more than 2 breaks/separations in any

channel, repeat the head cleaning and nozzle check process until sufficient results are attained.

Below are examples of both a good and poor nozzle check.

Good Nozzle Check

Poor Nozzle Check