30

SAMPLING THE FLUE GAS

Once the automatic calibration procedure has been completed and the specific fuel has been selected the

probe can be inserted into the desired sampling point.

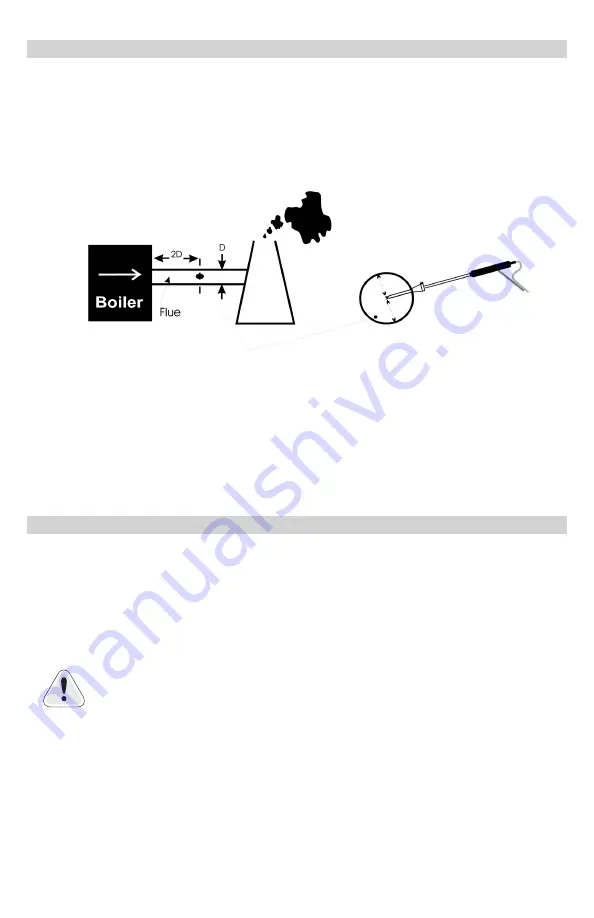

It is recommended that the sampling point be located at least two flue diameters downstream of any bend

and that the probe tip is in the center of the flue (this is normally the point of the hottest temperature).

With balanced flues and other industrial units the probe should be positioned far enough into the flue so

that no air can ‘back flush’ into the probe.

The probe depth stop cone provided with the instrument allows the probe to be used in holes whose

diameters range from 8 mm to 21 mm (5/16 to 4/5 inch).

The standard probe is rated at 650°C/1202°F. Temperatures of up to 100°C/2012°F can be accommodated

using an optional high temperature probe.

TIP:

To conserve battery power, switch off the pump when you are not taking a measurement. Use the

pump key to turn the pump ON and OFF.

LONG TERM MONITORING

There are a number of things that need to be considered for successful long term

unattended monitoring:

• The provision of enough power for the duration of the test

• The capability to empty the water trap

• Regular fresh air purging of the sensors

•

Protection from rain or water spray from the process being monitored.

If a mains power source is being used it is strongly recommended that the supply cable be pro-

tected by a suitable Residual Current Device (RCD).

Unless the water trap is to be regularly inspected then a pumped water trap should be fitted.

Electrochemical sensors need regular refreshing with fresh air, preferably at around 50% RH. They also

need a small percentage of oxygen to be present in the sampled gas. If there is zero oxygen the output

from the sensors will decay over time (10 minutes or so). In such circumstances, fresh air purge should be

programmed for a 50% duty cycle every 10 minutes.

The longest sampling time without purging should be limited to 2 hours and then purge for 30 minutes.

When the KHC infrared module is fitted, for maximum accuracy it is recommended that purging occur

every 30 minutes.

Summary of Contents for K9206

Page 29: ...29 ...