4

ADA15IM

ADA SERIES

Figure 2

2. Turn the adjusting screw

using a flat tip

screwdriver in a small increment clockwise for a COLDER

setting (slower ice production) or counterclockwise for

a WARMER setting (faster ice production).

3. Replace the front grille (two screws).

Ice Maker

When the ice bucket is full, the ice making mechanism will

shut off. However, the refrigeration system will continue

to cool and maintain the cube supply. Frost-free icemaker

units have lower ice production than manual defrost

units.

IMPORTANT

IMPORTANT

Do not place cans or bottles in the ice compartment

because they will freeze.

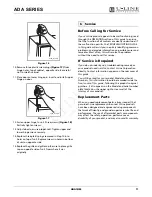

Figure 3

Ice production may be interrupted by raising the bin arm

into an upright and locked position

. The unit

will maintain temperature for ice storage.

IMPORTANT

IMPORTANT

If you are not intending to use the ice maker and

turn the supply valve off, it is imperative to raise

the bin arm of the ice maker (Figure 3). Failure to

raise the bin arm may result in damage to the water

valve.

Certain sounds are normal during the unit’s operation.

You may hear the compressor or fan motor, the water

valve, or ice dropping into the ice bucket.

WARNING

NEVER use an ice pick, knife or other sharp

instrument to separate cubes. Shake the ice

bucket instead.

During periods of limited usage or high ambient

temperatures, it is common for cubes to fuse together.

Shake the bucket to break apart cubes. If the ice maker is

not used regularly, the ice bucket should be emptied

periodically to ensure fresh cubes.

It is normal for cubes to appear cloudy. This is caused by

air being trapped in the water due to fast freezing. It has

nothing to do with the health, taste or chemical make-up

of the water. It is the same air that is in every glass of

water you drink.

The ice bucket can be removed for emptying and

cleaning. To remove the ice bucket, raise the bin arm and

remove the bucket from the ice compartment. Use the ice

bucket for ice storage only.

Normal Operating Sounds

All models incorporate rigid foam insulated cabinets to

provide high thermal efficiency and maximum sound

reduction for its internal working components. In spite of

this technology, your model may make sounds that are

unfamiliar.

Normal operating sounds may be more noticeable

because of the unit’s environment. Hard surfaces such as

cabinets, wood/vinyl/tiled floors and paneled walls have a

tendency to reflect normal appliance operating noises.

Common refrigeration components, and a brief

description of the normal operating sounds they make,

are listed below.

NOTE:

Your product may not contain all

of the components listed.

• Compressor: The compressor makes a hum or pulsing

sound that may be heard when it operates.

• Evaporator: Refrigerant flowing through an evaporator

may sound like boiling liquid.

• Condenser Fan: Air moving through a condenser may be

heard.

• Automatic Defrost/Drain Pan: Water may be heard

dripping or running into the drain pan when the unit is in

the defrost cycle.

C

OLDER

ULIN_0131_A

ULIN_0087_A