8

ADA15IM

ADA SERIES

Ice Maker Maintenance

Ice Cube Thickness Adjustment

Interval - As Required

On ice maker equipped models, the cube size may be

adjusted by changing the amount of water injected into

the ice maker assembly as follows:

Figure 5

1. Remove the ice maker assembly cover

.

Figure 6

2. Locate the adjusting screw on the ice maker assembly

control box. The adjusting screw is just below the minus

(-) and plus (+) signs on the control box

.

NOTE:

Make adjustments in small increments. Too

large of an adjustment could cause the unit to

malfunction.

CAUTION

Too large of an adjustment to the screw can cause

the water to overflow the ice maker and can cause

property damage.

3. Turn the adjusting screw toward the minus (-) sign

(clockwise) for smaller cubes or toward the plus (+) sign

(counterclockwise) for larger cubes.

4. Install the ice maker assembly cover.

IMPORTANT

IMPORTANT

Use only genuine U-Line replacement parts. U-Line

ice maker parts are not the same as standard FSP

Whirlpool parts. Using non U-Line parts can reduce

ice rate, cause water to overflow from ice maker

mold, damage the unit, and may void the warranty.

Leveling

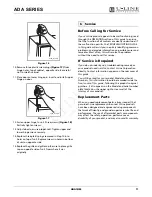

Figure 7

1. Use a level to check the levelness of the unit from front

to back and from side to side. Level should be placed

along top edge and side edge as shown

(Figure 8)

.

Figure 8

2. If the unit is not level, adjust the feet on the corners of

the unit as necessary

(Figure 9)

.

3. Check the levelness after each adjustment and repeat

the previous steps until the unit is level.

ULIN_0275_A

ULIN_0056_A

Place

level

here

ULIN_0043_A

1

ULIN_0044_A