– 52 –

Table 8-1-2

NOTE :

• UL : Ultra Low, SUL : Super Ultra Low

Operation

mode

COOL

DRY

HEAT

FAN

mode

H

M+

M

L

L–

UL

SUL

L–

SUL

H

M+

M

L

L–

UL

SUL

M10

Motor speed

Air flow rate

(rpm)

(m³/h)

1100

470

1100

470

1010

440

910

380

810

320

770

300

760

300

810

320

760

300

1200

520

1200

520

1100

470

930

390

930

390

810

320

670

260

M13

Motor speed

Air flow rate

(rpm)

(m³/h)

1200

520

1140

510

1050

470

910

380

820

330

770

300

760

300

820

330

760

300

1280

560

1280

560

1100

470

930

390

930

390

820

330

730

290

M16

Motor speed

Air flow rate

(rpm)

(m³/h)

1350

600

1300

580

1190

520

980

420

920

380

870

360

820

330

920

380

820

330

1350

600

1350

600

1200

520

980

420

980

420

920

380

730

290

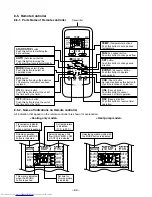

8-1-6. Louver Control

(1) Vertical air flow louvers

Positions of vertical air flow louvers are automati-

cally controlled according to the operation status

(AUTO, COOL, DRY, HEAT). Besides, positions of

vertical air flow louvers can be arbitrarily set by

pressing the [SET] button. The louver position which

has been set by the [SET] button is stored in micro-

computer, and the louver is automatically set at the

stored position in the next operation.

(2) Swing

If the [AUTO] button is pressed during running

operation, vertical air flow louvers start swinging.

When the [AUTO] button is pressed again, swinging

stops.

8-1-7. Indoor Fan Control (DC Fan Motor)

The indoor fan is operated by motor speed non-step

variable DC drive system motor. For flow rate, motor

speed is controlled manually in three steps (LOW,

MED, HIGH), and with the unit of 10 rpm from upper

limit to lower limit in AUTO mode as described in

Table 8-1-2. It is not selected by relay, so selecting

sound does not generate.

8-1-4. Prevent-Freezing Control

The indoor heat exchanger sensor detects refriger-

ant vapor temperature in COOL/DRY operation. If

the temperature is below the specified value, com-

pressor motor speed is reduced so that operation is

performed in temperature below the specified value

to prevent-freezing of indoor heat exchanger.

8-1-5. P. M. V. (Pulse Modulating Valve)

Using P.M.V., refrigerant flow of refrigeration cycle is

varied for the optimum temperature. Controlling

each unit separately by four P.M.V. corresponds to

difference of pipe length, fan speed, and unit tem-

perature.

If an error occurs on cycle temperature when power

source of the air conditioner has been turned on,

and if start/stop times of the outdoor unit are 30

times, move the valve once until it hits on the stopper

for positioning of the valve. In this case, ticktack

sound may be heard.