•

If you spill fuel on your clothing, change your clothing

immediately. Wipe up any fuel that spills.

•

Never overfill the fuel tank. Replace the fuel cap and

tighten it securely.

•

Store fuel in an approved container and keep it out of the

reach of children. Never buy more than a 30-day supply

of fuel.

•

Do not fill the fuel tank completely full. Add fuel to the

fuel tank until the level is 6 to 13 mm (1/4 to 1/2 inch)

below the bottom of the filler neck. This empty space in

the tank allows fuel to expand.

–

Avoid prolonged breathing of vapors.

–

Keep your face away from the nozzle and fuel tank

opening.

–

Avoid contact with skin; wash off spills with soap and

water.

Recommended Fuel

The engine runs on clean, fresh diesel fuel with a minimum

octane rating of 40. Purchase fuel in quantities that can be

used within 30 days to ensure fuel freshness.

Use summer-grade diesel fuel (No. 2-D) at temperatures

above -7°C (20°F) and winter-grade diesel fuel (No. 1-D or

No. 1-D/2-D blend) below -7°C (20°F). Use of winter-grade

diesel fuel at lower temperatures provides lower flash point

and pour point characteristics, therefore easing startability and

lessening chances of chemical separation of the fuel due to

lower temperatures (wax appearance, which may plug filters).

Using summer-grade diesel fuel above -7°C (20°F) contributes

toward longer life of the pump components.

Important:

Do not use kerosene or gasoline instead of

diesel fuel. Failure to observe this caution will damage

the engine.

Biodiesel Ready

This machine can also use a biodiesel blended fuel of up

to B20 (20% biodiesel, 80% petrodiesel). The petrodiesel

portion should be low or ultra low sulfur.

Observe the following precautions:

•

The biodiesel portion of the fuel meet specification

ASTM D6751 or EN14214.

•

The blended fuel composition should meet ASTM D975

or EN590.

•

Painted surfaces may be damaged by biodiesel blends.

•

Use B5 (biodiesel contend of 5%) or lesser blend in cold

weather.

•

Monitor seals, hoses, gaskets in contact with fuel as they

may degrade over time.

•

Fuel filter plugging may be expected for a time after

converting to biodiesel blends.

•

Contact your distributor if you wish for more information

on biodiesel.

Filling the Fuel Tank

1.

Park the machine on level ground.

2.

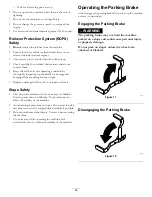

Shut off the engine and engage the parking brake.

3.

Clean around the fuel-tank cap.

4.

Fill the fuel tank to the bottom of the filler neck (

).

Note:

Do not fill the fuel tank completely full. The

empty space in the tank allows the fuel to expand.

16

Summary of Contents for Z593-D Z Master 74264TE

Page 75: ...Schematics g012068 g012068 Wire Diagram Rev A 75 ...

Page 76: ...Notes ...

Page 77: ...Notes ...

Page 78: ...Notes ...