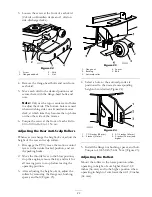

Figure 42

1. Air cleaner cover

5. Air cleaner indicator

2. Gasket

6. Air cleaner latch

3. Filter

7. Rubber outlet valve

4. Air cleaner body

•

Be sure the cover is seated correctly and seals

with the air cleaner body.

Servicing the Air Cleaner

1. Pull the latch outward and rotate the air cleaner

cover counter-clockwise (Figure 42).

2. Remove the cover from the air cleaner body

(Figure 42).

3. Before removing the filter, use low pressure

air (40 psi, clean and dry) to help remove

large accumulations of debris packed between

outside of primary filter and the canister.

This cleaning process prevents debris from

migrating into the intake when the primary

filter is removed.

Important:

Avoid using high pressure

air which could force dirt through the filter

into the intake tract.

4. Remove and replace the primary filter

(Figure 42).

Important:

Do not clean the used

element to avoid damage to the filter

media.

5. Inspect the new filter for shipping damage,

checking the sealing end of the filter and the

body.

Important:

Do not use a damaged

element.

6. Ensure that the foam gasket is in place in

the cover and that it is not torn or damaged

(Figure 42). If it is damaged, replace it.

7. Insert the new filter by applying pressure to

the outer rim of the element to seat it in the

canister.

Important:

Do not apply pressure to the

flexible center of the filter.

8. Clean the dirt ejection port located in the

removable cover, as follows:

A. Remove the rubber outlet valve from the

cover (Figure 42).

B. Clean the cavity.

C. Replace the outlet valve.

9. Install the cover orienting the rubber outlet

valve in a downward position—between

approximately 5:00 to 7:00 when viewed from

the end.

10. Reset the indicator (Figure 42) if showing red.

Servicing the Engine Oil

Checking the Engine Oil Level

The engine is shipped with oil in the crankcase;

however, the oil level must be checked before and

after the engine is first started. Check oil level

before each day’s operation or each time machine

is used.

The crankcase capacity is approximately 4 qt.

(3.8 l) with the filter. Use high-quality engine oil

that meets the following specifications:

•

API Classification Level Required: CH-4, CI-4

or higher.

•

Preferred oil: SAE 15W-40 (above 0°F (-17°C)

•

Alternate oil: SAE 10W-30 or 5W-30 (all

temperatures)

Note:

Toro Premium Engine oil is available

from your distributor in either 15W-40 or 10W-30

viscosity. See the parts catalog for part numbers.

1. Park the machine on a level surface, lower the

mower deck, move the throttle lever to the

Slow position, stop the engine, and remove the

key from the ignition switch. Open the hood.

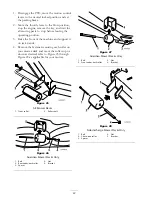

2. Remove the dipstick (Figure 43), wipe it clean,

and install the dipstick. Remove the dipstick

and check the oil level.

47

Summary of Contents for Groundsmaster 7200 Series

Page 9: ...Slope Chart 9 ...

Page 44: ...Figure 39 44 ...

Page 70: ...Schematics Electrical Schematic Rev A 70 ...

Page 71: ...Hydraulic Schematic Rev A 71 ...