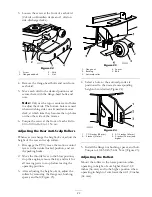

Figure 29

Side-discharge Mower Decks Only

1. Bolt

3. Under-deck roller (2)

2. Roller shaft

4. Bracket

5. Install the fasteners as illustrated.

The Safety Interlock System

If the safety interlock switches are

disconnected or damaged the machine

could operate unexpectedly causing

personal injury.

•

Do not tamper with the interlock

switches.

•

Check the operation of the interlock

switches daily and replace any damaged

switches before operating the machine.

Understanding the Safety Interlock

System

The safety interlock system is designed to prevent

the engine from starting unless:

•

You are sitting on the seat or the parking brake

is engaged.

•

The power take off (PTO) is disengaged.

•

The motion control levers are in the neutral

locked position

•

The engine temperature is below the maximum

operating temperature.

The safety interlock system also is designed to stop

the engine when the traction controls are moved

from the neutral locked position with the parking

brake engaged. If you rise from the seat when the

PTO is engaged there is a 1 second delay and then

the engine stops.

Testing the Safety Interlock System

Test the safety interlock system before you use

the machine each time. If the safety system

does not operate as described below, have an

Authorized Service Dealer repair the safety system

immediately.

1. Sitting on the seat, engage the parking brake

and move the PTO to on. Try starting the

engine; the engine should not crank.

2. Sitting on the seat, engage the parking brake

and move the PTO to off. Move either motion

control lever (out of neutral locked position).

Try starting the engine; the engine should not

crank. Repeat for other control lever.

3. Sitting on the seat, engage the parking brake,

move the PTO switch to off and move the

motion control levers to the neutral locked

position. Now start the engine. While the

engine is running, release the parking brake,

engage the PTO and rise slightly from the seat;

the engine should stop within 2 seconds.

4. Without an operator on the seat, engage the

parking brake, move the PTO switch to off and

move the motion control levers to the neutral

locked position. Now start the engine. While

the engine is running, center either motion

control; the engine should stop within 2

seconds. Repeat for the other motion control.

5. Without an operator on the seat, disengage

the parking brake, move the PTO switch to

off, and move the motion control levers to

the neutral locked position. Try starting the

engine; the engine should not crank.

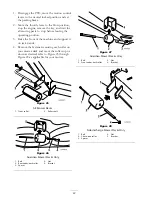

Using the SCM to Diagnose System

Problems

The machine is equipped with a standard control

module (SCM) monitoring system that tracks the

function of various key systems. The SCM is

located under the right control panel. Access it

through the side panel cover (Figure 30). To open

35

Summary of Contents for Groundsmaster 7200 Series

Page 9: ...Slope Chart 9 ...

Page 44: ...Figure 39 44 ...

Page 70: ...Schematics Electrical Schematic Rev A 70 ...

Page 71: ...Hydraulic Schematic Rev A 71 ...