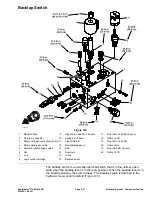

Diode Assembly

g223019

Figure 137

1.

End of the diode body

3.

Male terminal

2.

Diode assembly

4.

Female terminal

The diode assembly can be identified by a black color, diode symbol, and Toro

Part Number on the end of the diode assembly body (

). The diode

assembly can be located between the operator seat and hydraulic tank.

Testing

1. Park the machine on a level surface, lower the cutting units, shut off the

engine, set the parking brake, and remove the key from the key switch.

2. Locate the diode assembly that is to be tested and remove the cable tie

that secures the diode to the wire harness. Unplug the diode from the wire

harness for testing.

3. The diode (

) can be tested by using a digital multimeter (diode test

or ohms setting) and the

Diode Test Table (page 6–37)

.

4. Replace the diode assembly if testing determines that the diode is damaged.

5. After you complete the testing, ensure that the diode is fully installed into the

wire harness connector and secured to the harness with cable tie.

Diode Test Table

Multimeter Red Lead (+)

on Terminal

Multimeter Black Lead

(-) on Terminal

Continuity

Female

Male

Yes

Male

Female

No

Reelmaster

®

3100-D/3105-D

Page 6–37

Electrical System: Component Testing

20252SL Rev A

Summary of Contents for 03200 Reelmaster 3100-D

Page 4: ...NOTES NOTES Page 4 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 6: ...g341979 Figure 1 Preface Page 6 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 10: ...Preface Page 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 20: ...Safety Safety and Instructional Decals Page 1 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 44: ...Specifications and Maintenance Special Tools Page 2 24 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 224: ...Hydraulic System Service and Repairs Page 5 148 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 385: ......