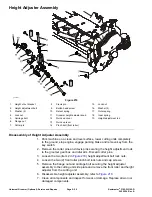

Assembling the Gear Box Assembly (continued)

8. Fit gear box cover over dowel pins and install four (4) socket head screws.

Tighten screws from

2 to 4 N·m (15 to 40 in-lb)

. In an alternating cross

pattern, tighten four (4) socket head screws from

8 to 9 N-m (75 to 85 in-lb)

.

9. Fill the gear box with 80W-90 gear oil and tighten drain/fill plug from

4 to 5

N·m (32 to 52 in-lb)

.

Gear box oil capacity for 7 in. reel cutting units = 90 cc (3 oz.)

CAUTION

Use the 1-3/8” flats on the input shaft to prevent the input shaft from

rotating during adapter installation. DO NOT use the 1/2” hex on the

input shaft to secure the shaft during adapter installation or input

shaft damage may occur.

10. If removed, install the threaded adapter in the input shaft. If reusing a

previously installed threaded adapter, apply medium strength thread locker to

the smaller (5/8-11) threads only. Tighten threaded adapter from

156-196

N·m (115-125 ft-lb)

.

11. Operate groomer gear box by hand to check for proper operation prior ro

installation.

Installing the Gear Box Assembly

1. Park machine on a clean and level surface, lower cutting units completely

to the ground, stop engine, engage parking brake and remove key from the

key switch.

CAUTION

Contact with the reel or other cutting unit parts can result in personal

injury. Use heavy gloves when handling the cutting reel.

2. Safely prevent reel from rotating by blocking the cutting reel with piece of

wood near one of the reel spiders.

IMPORTANT

Groomer gear boxes installed on the left side of the cutting unit

use a left hand thread. Turn the input shaft (rear roller brush drive

shaft) counterclockwise to install the gear box. Groomer gear boxes

installed on the right side of the cutting unit use a right hand thread.

Turn the input shaft clockwise to install the gear box.

Reelmaster

®

3100-D/3105-D

Page 9–11

Universal Groomer (Optional): Service and Repairs

20252SL Rev A

Summary of Contents for 03200 Reelmaster 3100-D

Page 4: ...NOTES NOTES Page 4 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 6: ...g341979 Figure 1 Preface Page 6 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 10: ...Preface Page 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 20: ...Safety Safety and Instructional Decals Page 1 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 44: ...Specifications and Maintenance Special Tools Page 2 24 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 224: ...Hydraulic System Service and Repairs Page 5 148 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 385: ......