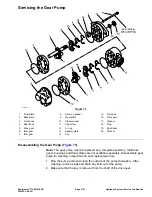

Gear Pump

g345934

Figure 73

1.

Piston pump

7.

O−ring

13.

Flat washer

2.

Gear pump

8.

O−ring

14.

O−ring

3.

Hydraulic hose (tank suction)

9.

Hydraulic barb fitting

15.

O−ring

4.

Hydraulic hose (hydraulic manifold) 10.

90º hydraulic fitting

16.

O−ring

5.

Hydraulic hose (steering valve)

11.

90º hydraulic fitting

6.

Hose clamp

12.

Cap screw

Removing the Gear Pump

1. Park the machine on a level surface. Lower cutting units, stop engine and

engage parking brake. Remove key from the key switch. Raise and support

hood.

2. Remove muffler from the engine to gain access to the gear pump (see

Removing the Exhaust System (page 4–7)

).

WARNING

Before disconnecting or performing any work on the hydraulic

system, all pressure in the system must be relieved. See

Hydraulic System Pressure (page 5–3)

.

3. Thoroughly clean the hydraulic hose ends and fittings on gear pump to

prevent hydraulic system contamination.

Hydraulic System: Service and Repairs

Page 5–88

Reelmaster

®

3100-D/3105-D

20252SL Rev A

Summary of Contents for 03200 Reelmaster 3100-D

Page 4: ...NOTES NOTES Page 4 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 6: ...g341979 Figure 1 Preface Page 6 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 10: ...Preface Page 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 20: ...Safety Safety and Instructional Decals Page 1 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 44: ...Specifications and Maintenance Special Tools Page 2 24 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 224: ...Hydraulic System Service and Repairs Page 5 148 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 385: ......