The Standard Control Module (SCM) monitors the operation of the parking brake

switch. If the key switch is in the ON position and the parking brake is released,

the SCM parking brake off input LED should be illuminated.

Testing

1. Park the machine on a level surface, lower the cutting unit, and shut off the

engine.

2. Before you disconnect the parking brake switch for testing, ensure that you

test the parking brake switch and its circuit wiring as a SCM input; refer to

Standard Control Module (SCM) (page 6–45)

.

3. If the SCM verifies that the switch and circuit wiring are functioning correctly,

then no more switch testing is necessary.

4. If the SCM determines that the parking brake switch and circuit wiring are not

functioning correctly, proceed with the test.

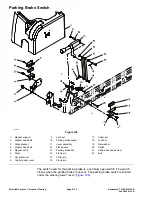

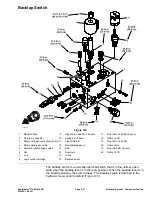

5. Remove cover from control panel to gain access to parking brake switch.

6. Locate the parking brake switch.

7. Make sure key switch is OFF and disconnect the parking brake switch

connector from machine wire harness.

8. Connect a multimeter (ohms setting) across the switch connector terminals

to check the continuity of the switch as follows:

A. When the switch plunger is extended, there should not be continuity

between the switch terminals.

B. When the switch plunger is pressed, there should be continuity between

the switch terminals.

9. Replace the switch if testing determines that the switch is damaged.

10. If the parking brake switch testing is correct and a circuit problem still exists,

check the main wire harness; refer to the Electrical Schematics and Wire

Harness Drawings/Diagrams in

Appendix A (page A–1)

.

11. After you complete the parking brake switch testing, connect the switch

connector to the machine wire harness.

12. Install cover to control panel.

Reelmaster

®

3100-D/3105-D

Page 6–23

Electrical System: Component Testing

20252SL Rev A

Summary of Contents for 03200 Reelmaster 3100-D

Page 4: ...NOTES NOTES Page 4 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 6: ...g341979 Figure 1 Preface Page 6 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 10: ...Preface Page 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 20: ...Safety Safety and Instructional Decals Page 1 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 44: ...Specifications and Maintenance Special Tools Page 2 24 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 224: ...Hydraulic System Service and Repairs Page 5 148 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 385: ......