21

2.5.3 System Integration

You can incorporate this instrument into one system and use it under the incorporated status. To use

the instrument under the incorporated status in system, refer to the following chapters.

Communication specification:

☞

“4.Communication with PC”.

Installation data:

☞

“External Dimensional Diagram” of “6. Appendices”

2.5.4 Measuring a Frequency Light Source

To measure a light source lighting by frequency, follow the procedures described below.

■

When measuring with “FREQ” (frequency) mode

When the lighting frequency of the light source is known, set the measurement mode to “FREQ”

(frequency). Input the frequency and measure the light source.

☞

In “FREQ” mode, the integral time is automatically set to the value obtained by multiplying one

cycle by integers. So the discrepancy can be reduced in measurement.

■

When measuring with “AUTO” mode

When measuring a light source equipped with a high duty ratio and a high light intensity or a light

source where a dummy (black) enters during the lighting cycle period by using “AUTO” mode,

the sufficient flashing times cannot be obtained in the set integral time and so big discrepancy

occurs in the measured values. (Refer to the following example.) Setting the integral time

longer than usual is useful to reduce discrepancy. By using the integral time delay function, the

integral time is longer and measurement is done in stabilized condition.

☞

“3.3 Integral Time Delay Function”.

Set the measurement mode to “AUTO”, set the integral time delay function to ON and set the

delay time.

We recommend approx. 100 cycles or more as the delay time.

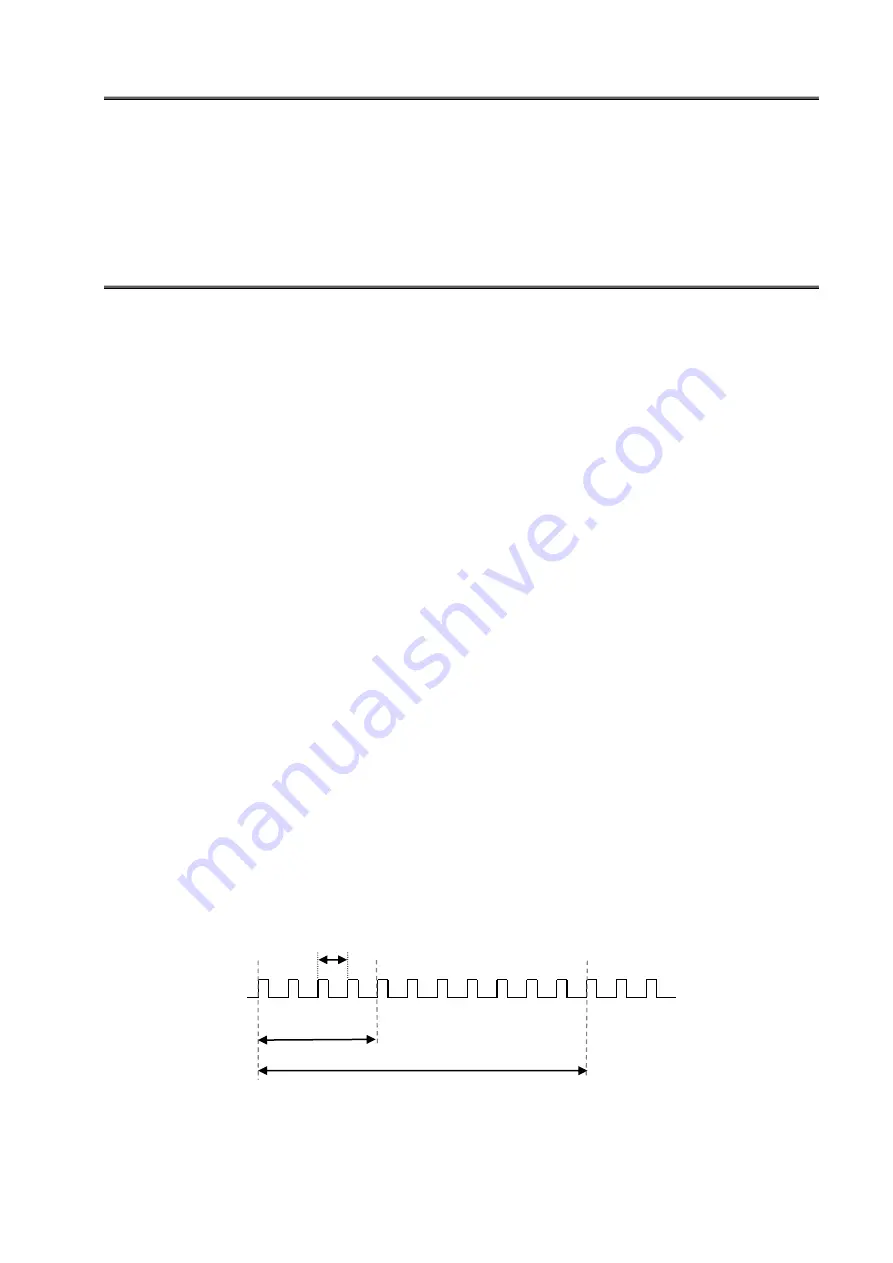

Example: When discrepancy 10% of one cycle occurs (Refer to the following figure.)

• Measure with the integral time of 10 cycles (t: One cycle time).

Discrepancy = 0.1 t/10 t = 1%

• Measure with the integral time of 100 cycles.

Discrepancy = 0.1 t/100 t = 0.1%

Setting the longer integral time reduces discrepancy.

t (One cycle)

Integral time (“n” times of “t”)

Integral time

(“n” times of “t”)