UM-12

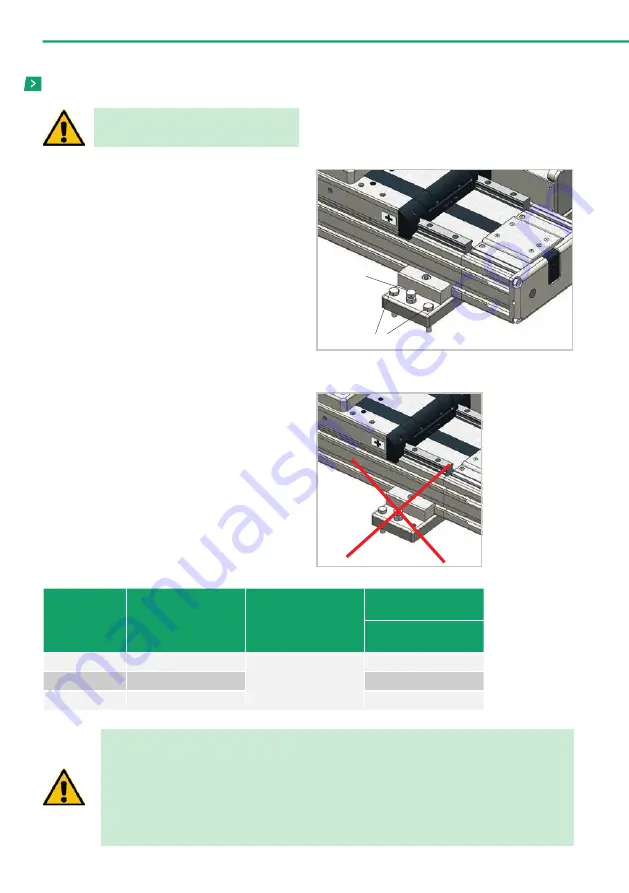

After placing the axis in its work position, turn the leveling

screws to align it as desired and to compensate for possible

misalignments due to irregular mounting surfaces. After lev-

elling, tighten the two fixing screws with the torque indicated

in the table.

Installation:

1. Position the axis with all leveling screws in full raised po-

sition;

2. Adjust the screws to achieve the desired alignment;

3. Fasten the fixing screws alternately and progressively. Do

not fix a screw completely while having the other com-

pletely unfastened. Both should be tightened progressively

and alternately until the specified torque is reached.

If the bolt provided is not of a suitable length, it can be re-

placed with one of a different length but of the same type

and property class.

Fig. 8

Fig. 9

Anchoring the CTU

Leveling screw

Fixing screws

Fasten both fixing screws

Hexagon head bolt with

shank UNI 5737

Friction coefficient

Tightening torque [Nm]

Property class 10.9

CTU130-1I

M8x40

0.15

34

CTU160-1I

M10x50

67

CTU220-1I

M10x50

67

Tab. 5

Power down the system while any operation

of assembly/disassembly is performed.

IMPORTANT!

All screws used for installing Rollon modules have “self-locking” washers or semi-permanent “threadlock”

fluid (blue, such as Loctite 243). We recommend that the user also employ these devices, both while setting

up the partially assembled machine described in this manual, and during the assembly or maintenance

phases: if this is not done, the manufacturer of the partially assembled machine declines all responsibility

for any accidents, breakage, damage and the consequences of said events on people, animals and property,

due to the failure of fixing elements.

4 Installation instructions

Summary of Contents for ROLLON CTU 220-1I

Page 2: ......

Page 44: ...UM 42 Notes Notes...

Page 45: ...UM 43 Cobot Transfer Unit Notes...

Page 46: ...UM 44 Notes Notes...

Page 47: ......