Installation, use and maintenance guide

COMPACT S22

–S26–S32 EVO5

Page

32

ENG

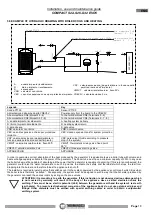

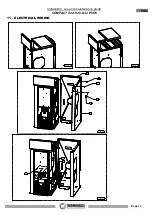

In systems configured like the nearby diagram, where the appliance is installed in a

system fitted with both a boiler tube and a puffer.

Activate the THERMOCONTROL function to control the puffer and the THERMO

ACS function to control the boiler tube. With this logic the appliance controls the

ON/OFF cycles automatically according to the heat requests from both the puffer and

the boiler tube. Precedence is always given to the boiler tube, and once satisfied, the

appliance switches the 3-way valve and diverts the heat to the puffer and when it is

satisfied it switches OFF.

When is it important to use the THERMO ACS function together with the

TAMBIENT function?

In systems configured like the nearby diagram, where the appliance is connected

directly to a domestic hot water boiler tube and to the system.

When using this function the generator starts up automatically when the boiler

tube is running out of heat.

Once the boiler tube is satisfied, the appliance gives consent for the 3-way valve

to switch over in order to supply the system with heat. When the room

temperature is satisfied the appliance turns to the OFF position, and waits for the

next request for heat from the boiler tube or the room.

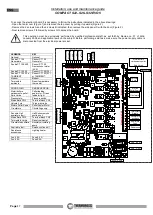

6.10 OPERATION OF THE GENERATOR

6.10.1 DESCRIPTION OF THE OPERATING STAGES

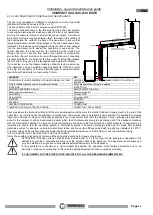

START:

has a duration of approx. 20 minutes, during this phase the

appliance is programmed to light the flame. The appliance will not

accept power variations in the firebox. If the appliance does not start

up correctly it could be due to one of the following factors:

cleanliness of the generator, smoke exhaust particularly cold, sudden

surges and drops in the electric power supply, fuel is too moist or

does not comply with the specifications.

WORK

: the duration depends on the ability of the system to receive heat.

The generator's operating status is displayed. During this stage the

brazier cleaning mechanism “Pellet Power”, that is, the device installed

inside the brazier, moves in timed mode.

OFF:

has a duration of approx. 25 minutes. In this phase the appliance is

switched off until a new "on" phase is initiated. The aim is to make the

pellet embers in the brazier die out. A few seconds aftet the activation of the OFF cycle the brazier cleaning mec

hanism “Pellet

Power”, that is, the device installed inside the brazier, moves in continuous mode. After approx. 25 minutes the appliance goes to

standby and the brazier cleaning mechanism “Pellet Power” stops.

ATTENTION:

It is recommended to verify at least once a month that when the appliance is in OFF mode in the time

interval specified above, the brazier cleaning mechanism “Pellet Power” operates in continuous mode to clean the

brazier.

STOP:

If the temperature of the appliance exceeds the 80°C threshold, the momentary shut off, identified as STOP, is activated.

ATTENTION: The STOP phase allows the generator to begin a new START phase only when the temperature drops below 58°C.

ATTENTION: The STOP mode must be considered an overtemperature pre-allarm, and therefore cannot be considered a normal

operating stage.

WAIT ON

: when the appliance is restarted while hot where the water temperature is higher than 63°C the appliance does not start

immediately, but the circulating pump will still be active. The message WAIT ON appears on the display. A new startup procedure

will not begin until the temperature drops to 58°C. The text START will appear on the screen.

SUN OUT:

this function only activates automatically if the THERMOCONTROL function is turned to ON and if solar panels are

connected to the puffer. When Sensor S2 detects a temperature over 80°C and the appliance is in OFF mode, the text SUNOUT

will appear on the display accompanied by the circulating pump active indicator and activation of the smoke suction unit at the

maximum power.

Legenda

Key

Temperatura acqua

generatore (°C)

Generator water

temperature (°C)

Avvio

Start

Lavoro

Running

Off

Off

Tempo (minuti)

Time (minutes)

Il presente disegno è di proprietà esclusiva di THERMOROSSI S.p.A.. La riproduzione totale e/o parziale e la divulgazione a terzi, senza nostro esplicito consenso scritto, verrà perseguito secondo i termini di legge in vigore.

Scala

Locazione file

Data

F

irm

a

Foglio

Note

Materiale

Prodotto

Sviluppo

1/1

TEL. 0445-741310 - FAX 0445-741657

Via Grumolo, 4 - 36011 ARSIERO (Vicenza) - ITALY

S.p.A.

Spessore

Approv

.

D

at

a

appro

v

.

Formato

6_10

Cod.

Disegnatore

Volume

Peso

Colore

Revisione

Descrizione

Revisione

Autore

Data

Descrizione

LAMIERA

Il fornitore è responsabile della corretta realizzazione del

particolare come indicano le viste di progetto; lo sviluppo

piano deve essere verificato ed eventualmente modificato dal

fornitore in funzione delle macchine di piegatura che

andranno a realizzare il particolare.

STAMPI E FUSIONI

É obbligo da parte del fornitore, prima di

realizzare qualsiasi attrezzatura, fornire a

THERMOROSSI S.p.A. i file

tridimensionali dei particolari definitivi

X

Te

m

perat

u

ra

acqu

a

ge

nerat

o

re

(°

c

)

Avvio

Lavoro

OFF

tempo(minuti)

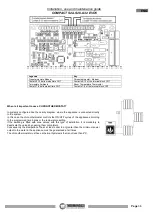

Potenza di funzionamento

5

4

3

2

1

61°c

65°c

Intervallo modulazione con T max 65°c

STOP

80°c

Potenza di funzionamento

5

4

3

2

1

61°c

70°c

Intervallo modulazione con T max 70°c

STOP

80°c

Potenza di funzionamento

3

61°c

STOP

80°c