30

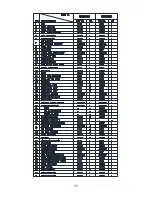

INITIAL

SERVICE

SERVICE

SERVICE

DRAFT -BREECH (IN W.C.)

DRAFT - OVERFIRE (IN W.C.)

DATE

CUSTOMER

HEATING

SYSTEM

COMBUSTION

TEST

Operate burner

for at least 10

min. before

taking

readings.

NOZZLE (GPH/ANGLE/CONE)

PUMP PRESS (PSI)

SAFTEY CONTROL OPERATION

CHECK FOR LEAKS

TECHNICIAN

ROOM TEMP (°F)

EFFICIENCY (%)

SUPPLY TEMP (°F)

RETURN TEMP (°F)

TEMP RISE (°F)

CO2 (%)

O2 (%)

GROSS FLUE TEMP (°F)

NAME

ADDRESS

CITY, STATE

FURNACE SERIAL

FURNACE MODEL

BURNER MODEL NO.

INSTALLER

NAME

ADDRESS

PHONE

TYPE OF VENTING & OIL SYSTEM (CHECK ALL THAT APPLY)

□

SIDEWALL POWER

VENTER

□

DRAFT CONTROL

□

FUEL FILTER

□

2 PIPE SYTEM

□

MASONRY CHIMNEY

□

DIRECT VENT

□

COMBUSTION AIR KIT

□

CLAY LINER

□

METAL LINER

□

METAL CHIMNEY

□

MAKE UP AIR TO

MECANICAL ROOM

CO (PPM)

SMOKE NO.

APPENDIX A: STARTUP SHEET

Combustion and Efficiency Testing for Oil Fired Furnaces:

Complete this form for each oil furnace installed. Read instruction manual carefully before taking

test. Retain this form with furnace.

Summary of Contents for OD6FA072D48

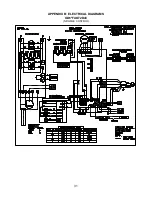

Page 32: ...31 APPENDIX B ELECTRICAL DIAGRAMS OD6 FAO72D48 NRGMAX CONTROL...

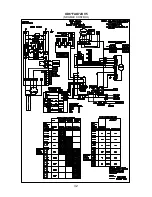

Page 33: ...32 OD6 FAO72DV5 NRGMAX CONTROL...

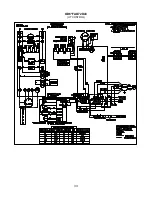

Page 34: ...33 OD6 FAO72D48 UT CONTROL...

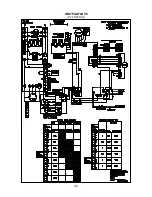

Page 35: ...34 OD6 FAO72DV5 UT CONTROL...

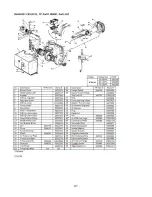

Page 37: ...36 APPENDIX D REPLACEMENT PARTS OD6FA072D48 OD6FA072DV4...

Page 38: ...37...

Page 39: ...38 OD6RA072D48 OD6RA072DV4...

Page 40: ...39...

Page 41: ...40...

Page 42: ...41...

Page 43: ...42...