ISU-689:2016/GB

7

3.6. Selection of expansion vessel

The boiler is not equipped with an expansion vessel, the vessel must

be mounted on the installation. In installation with additional

hydraulic coupling or plate heat exchanger, an individual expansion

vessel should be installed in the boiler

’s

circuit. A proper expansion

vessel should be selected by the designer of central heating system.

Installation of expansion vessel should be made by an installation

contractor in accordance with applicable regulations.

3.7. Condensate outlet

Each boiler has a condensate drainage system installed and already

connected.

The flexible pipe for condensate drainage must be connected to the

condensate collection and removal system in accordance with the

applicable regulations. The designer, considering the power of the

installation and the utility of the building, should adapt the system to

neutralization of the resulting condensate. The condensate drain

installation must be made of corrosion-resistant material.

The installation should be carried out in a way that prevents the

condensate from freezing. Check the condensate drain before

starting.

The connection of drain the condensation water cannot be

blocked.

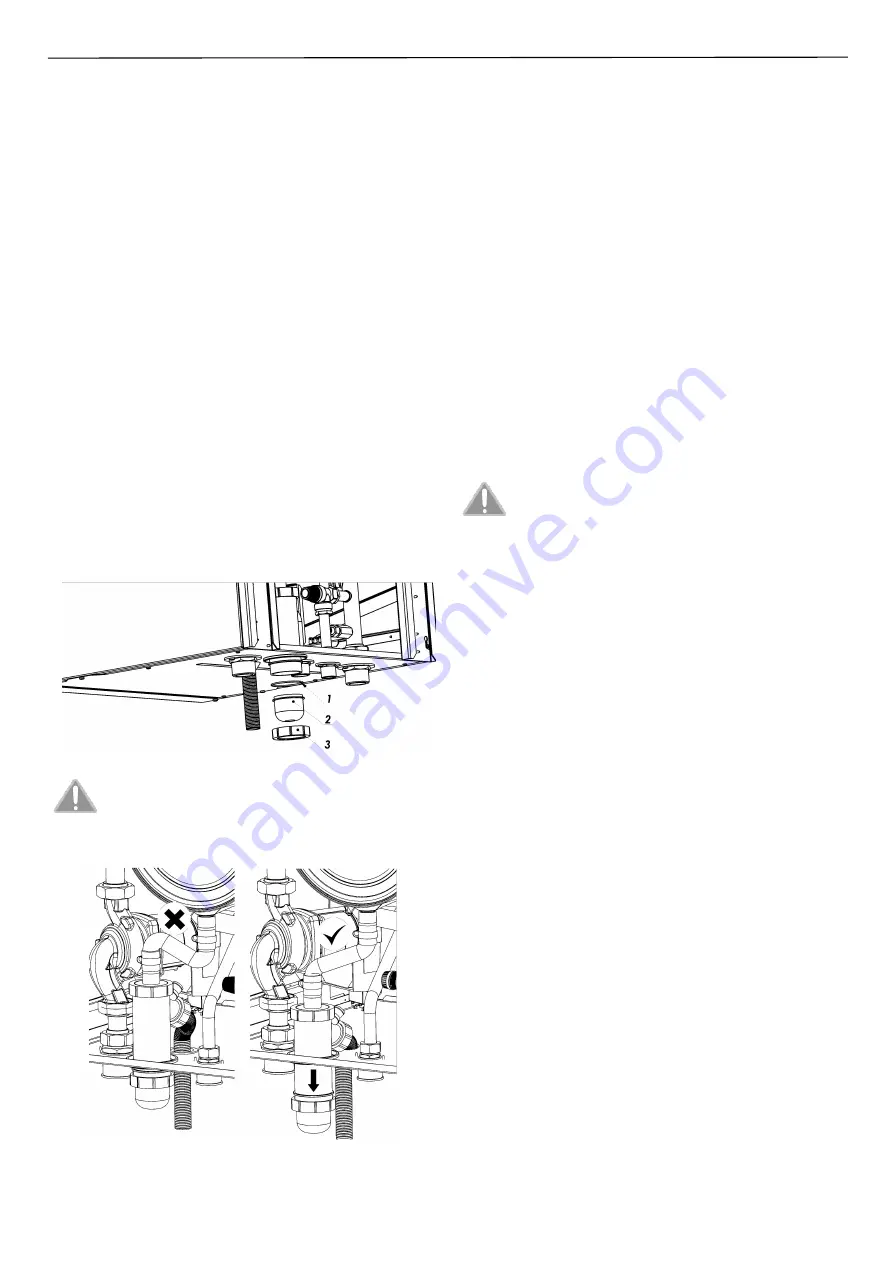

The bottom of the siphon (2) was dismantled during transport. All

parts necessary for installation: 1-gasket, 2-bottom of siphon, 3-nut,

are in the package of the boiler. Before starting the boiler, the siphon

should be assembled in accordance with Fig. 3.7.1.

Fig. 3.7.1

–

Mounting the siphon

Before the start-up of the boiler move the siphon to the

lowest position, to enable the hose (which connect heat

exchanger with siphon) to a proper condensate outlet

(see the Fig. below). A bent hose may cause the flooding of

heat exchanger by produced condensate.

During the start-up or after a long downtime, make sure that the

condensate is properly drained through the drain (E) see Fig 3.4.1.

3.8. Flue gas outlet

Flue gas outlet from the boiler must be made in accordance with

applicable regulations and this instruction manual and it needs to be

agreed with the district chimney sweep service company.

For flue systems, the boiler is made according to type: C13, C33, C43,

C63, B23.

•

it has closed combustion chamber in relation to the room where it

is installed (C),

•

is adjusted to be connected to separately approved and marketed

air-flue gas systems,

•

it is equipped with a blowing fan (3).

The boiler is designed for cooperation with the flue gas

–

air system

with a diameter of

Φ

100 (flue gas and air) and in a collective

cascade system where the flue gas exhaust from a single boiler is

realized by a pipe with diameter of

Φ

100. To install the flue gas

–

air

system to the boiler, it is recommended to mount the flue gas

adapters according to this manual, the adapters are supplied with

the boiler and are added to the boiler

’s

package.

Other components of the flue gas

–

air system of the boiler should be

purchased according to the design of the installation.

The boiler is factory adjusted with mounted exhaust

pipe

Φ

100 of the maximum length 0,5m without air

pipe. Settings CO

2

–

9% for natural gas. To use the other

systems and longer pipes it is required to adjust the

boiler as specified in point 4.3.

Connections and chimney duct must be designed and constructed in

accordance with applicable regulations. They must be made of

suitable material. They also must be corrosion-resistant, smooth

inside and tight, impervious to condensate.

Use the appropriate wire size (diameter, maximum length, resistance

on the knees), depending on the combustion system used. The

dimensions of the wires should be adequately compatible as given in

table. Resistance of flue gas flow on each elbow depending on the

bending angle and related reduction of the maximum wire length are

given in section 3.8.2.

Connection of the boiler to the air-flue gas system and installation of

the system itself should be sealed. Each system should be installed

with the windproof outlet protecting against external factors.

Before turning on the boiler check if flue-gas system is made

according to the project and air- and flue ducts lengths are shorter

than maximum lengths showed in above tables. Make sure flue-gas

system is tight.

After turning on the boiler check if it operates correctly. Also check

combustion parameters by checking concentration of CO

2

and/or O

2

in flue-gas.

3.8.1. Configuration Type B with open chamber and forced

draft

The air is sucked directly from the environment in which the boiler is

installed through the hole made in the boiler

’s

top cover. The

exhaust outlet should be connected to your own single chimney or

directed directly to the outside of the building according to the

requirements of applicable regulations.

Boilers with open combustion chamber type B can not be installed in

rooms exposed to vapors or volatile substances (e.g. vapors of acids,

paints, adhesives, solvents, fuels, etc.), as well as areas dusty with

wood, coal, cement, etc.