ISU-689:2016/GB

16

In a winter time (due to the risk of freezing water in

the system) the disconnection the boiler from

electrical system is forbidden (if there is still water in

the water system of the boiler).

Empty the boiler by means of a valve mounted inside the boiler

(2.22).

6. MAINTENANCE, INSPECTIONS, CHECKING OF THE

OPERATION

6.1. Inspection and maintenance

The boiler should be regularly serviced and subjected to

maintenance. At least once a year it is recommended to

perform a service and it should be reviewed before

heating season. All service and maintenance works

should be performer by an authorized person. Only

original parts should be used for boiler repairs. At every

service and maintenance works the tightness of the gas

units and gas installation and correctness of the

protective systems should be checked. The warranty

does not cover above mentioned operations.

6.1.1. Preparing the boiler for service

Before each cleaning or replacement of components,

ALWAYS disconnect the power supply as well as water

and gas supply of boiler. The manufacturer is not liable

for any damages caused by failure to follow the above

recommendations.

For easier maintenance, it is recommended to remove the casing as

follows.

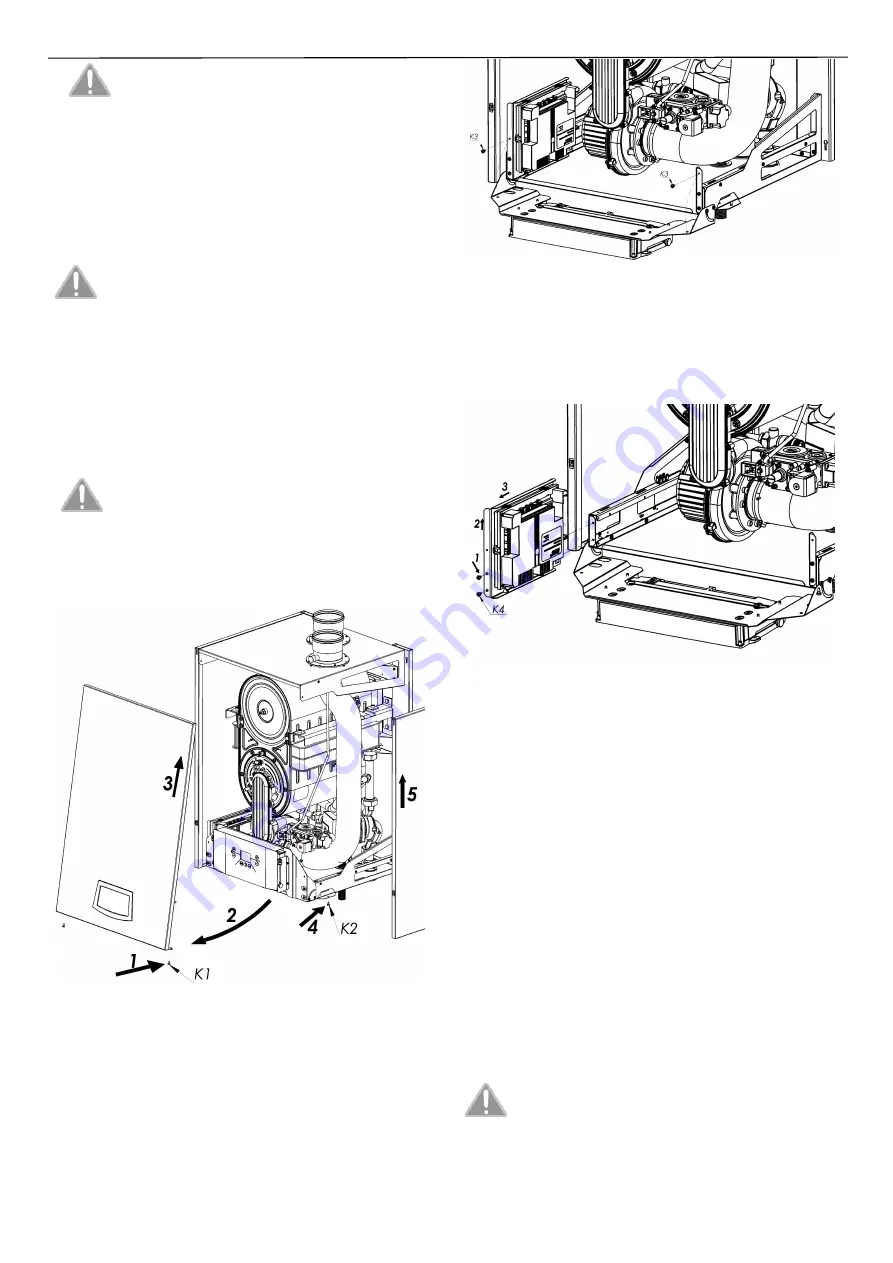

Fig. 6.1.1.1

–

Removing the front cover

Dismantling the front cover:

1. Loosen the screws (K1),

2. Pull the cover behind its lower edge to release from the latches,

3. Move the cover up.

Dismantling the side cover:

4. Unscrew the screws K2.

5. Move the cover up.

Fig. 6.1.1.2

–

Deflecting the controller bracket

In order to facilitate access to the boiler

’s interior

, the controller

must be lowered together with the bracket on which it is mounted,

for this purpose:

1. Unscrew the screws (K3),

2. Lower the bracket until locked.

Fig. 6.1.1.3

–

Dismantling of the controller

If it is necessary to remove the controller (2.7) after removing the

front cover and deflecting the console, you must:

Remove all wires connected to the controller.

1. Unscrew the screws (K4)

2. Move the controller up and then pull out of the boiler.

6.1.2. Maintenance of the combustion chamber, burner,

ignition electrode and ionization electrode

The interior of the combustion chamber, burner surface and the

electrodes should be checked by visual inspection:

•

the contaminated burner and the interior of the combustion

chamber may be cleaned with a brush made of plastic,

•

visible on the surface of the burner gaps and deformations

disqualify burner - replace the burner,

•

clean the electrodes with a plastic brush,

•

deformed electrodes should be replaced,

•

check the condition of insulators of all electrodes,

•

clean dirty insulators,

•

insulators with visible damages disqualify the electrodes

–

to be replaced.

Dirty burner and the interior of combustion chamber

mean that the boiler regulation must be done.