MAINTENANCE

3Ć19

186 MM159 (6–94)

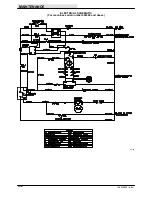

BELTS AND CHAINS

PROPELLING BELTS

The propelling belts transfer power from the

engine to the machine differential. Check the belts

for wear and tension after every 50 hours of

operation.

TO CHECK AND ADJUST PROPELLING BELTS

TENSION

1. Park on level surface. Stop the engine and

set the machine parking brake.

FOR SAFETY: Before Leaving Or Servicing

Machine; Stop On Level Surface, Set Parking

Brake, And Turn Off Machine.

2. Remove the engine access cover, right side

bumper and cover.

3. Observe the position of the clutch plate bolt

with no pressure on the clutch handle. It

should be approximately in the center of the

slot.

4. Press the clutch handle to tighten the

forward propelling belt. The clutch handle

should be at least 0.75 in (20 mm) from the

stationary handle for machines below serial

number 006000. The clutch handle should

be 0.25 to 0.50 in (7 to 13 mm) from the

stationary handle for machines serial

number 006000 and above. Observe the

position of the clutch plate bolt. It should not

touch the end of the slot. If the handle and

bolt are in the proper position, skip to step 8;

if not, continue with step 5 to readjust

forward belt tension.

A

B

C

D

H

G F

E

I

03151

PROPELLING BELTS

A. Engine

B. Clutch Plate

C. Clutch Plate Bolt

D. Bolt Slot

E. Forward Belt Idler Sheave

F. Reverse Propelling Belt

G. Forward Propelling Belt

H. Reverse Belt Idler Sheave

I. Belt Guide

5. Loosen the forward idler sheave bolt and

slide the idler sheave down to tighten the

belt (this also increases distance between

clutch handle and stationary handle); slide

the sheave up to loosen the belt (this also

reduces distance between clutch handle and

stationary handle).

6. Tighten the idler sheave bolt.

7. Recheck handle and bolt positions. Repeat

as necessary to adjust belt tension.

NOTE: After adjusting the forward belt, it may

contact the belt guide when engaged causing a

whining noise. To stop the noise, bend the guide

up out of the belt’s way.

8. Pull the clutch handle to tighten the reverse

propelling belt. Observe the position of the

clutch plate bolt. It should not touch the end

of the slot. If the bolt is in the proper

position, skip to step 12; if not, continue with

step 9 to readjust reverse belt tension.

NOTE: If the reverse belt is too tight, it will require

excessive clutch handle pressure to propel

machine in the forward direction. It may also

cause the machine to creep backward when the

handle is released.

Summary of Contents for 186

Page 1: ...186 MM159 Rev 05 12 95 Operator Manual ...

Page 10: ...SPECIFICATIONS 186 MM159 6 94 1Ć2 ...

Page 14: ...OPERATION 186 MM159 6 94 2Ć2 ...

Page 84: ...MAINTENANCE 186 MM159 6 94 3Ć48 ...

Page 86: ...APPENDIX 186 MM159 6 94 4Ć2 ...

Page 88: ...APPENDIX 186 MM159 6 94 4Ć4 ...