MAINTENANCE

186 MM159 (6–94)

3Ć8

ENGINE

ENGINE LUBRICATION

Check the engine oil level daily. Change the

engine oil after every 25 hours of operation. Use a

straight SAE 30-weight, API class SF engine oil. If

multiviscosity oil is used, oil consumption and

combustion deposits will increase.

Using other than service class SF oil or extending

oil change intervals could cause engine damage

not covered by the engine warranty.

The engine oil capacity is 1 qt (0.95 L).

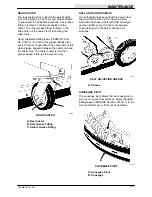

COOLING SYSTEM

Maintaining cooling system efficiency is important.

Engine temperatures must be brought up to and

maintained within the satisfactory range for

efficient operation. However, the engine must be

kept from overheating in order to prevent damage

to the valves, pistons, and bearings.

Clean the engine cooling fins after every 25 hours

of operation.

FOR SAFETY: When Servicing Machine, Wear

Eye And Ear Protection When Using

Pressurized Air Or Water.

AIR INTAKE SYSTEM

The importance of maintaining an air filter in

proper condition cannot be overemphasized. Dirt

induced through improperly installed, improperly

serviced, or inadequate air filter elements wears

out more engines than long hours of operation.

Even a small amount of dirt will wear out a set of

piston rings in just a few hours. Operating with a

clogged air filter element also causes the fuel

mixture to be richer, which can lead to formation

of harmful sludge deposits in the engine. Always

cover the air intake when the air cleaner is

removed for servicing. Do not neglect servicing

the air cleaner. Use only correct parts for

replacement. Keep all other air intake

components such as hoses, clamps, etc., secure

and in good condition to prevent entrance of

unfiltered air.

AIR FILTER

The engine air filter is made up of two parts, a

foam pre-cleaner and a dry cartridge type filter.

The foam pre-cleaner must be cleaned and

re-oiled after every 25 hours of operation. The dry

cartridge type filter should be cleaned or replaced

after every 100 hours of operation. The filter

element must be replaced if it is damaged or has

been cleaned three times.

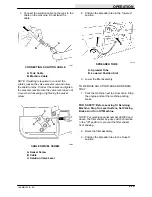

TO CLEAN OR REPLACE AIR FILTER

ELEMENT

1. Stop the engine and set the machine

parking brake.

FOR SAFETY: Before Leaving Or Servicing

Machine; Stop On Level Surface, Set Parking

Brake, And Turn Off Machine.

2. Open the filter cover to gain access to the

engine.

3. Remove the air filter cover wing nut.

4. Remove the air filter cover.

A

B

C

D

03074

ENGINE AIR FILTER

A. Foam pre-cleaner

B. Dry Cartridge Air Filter

C. Wing Nut

D. Air Filter Cover

5. Remove the foam pre-cleaner.

6. Wash the foam pre-cleaner in liquid

detergent and water.

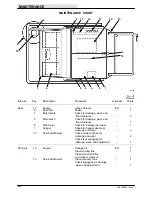

Summary of Contents for 186

Page 1: ...186 MM159 Rev 05 12 95 Operator Manual ...

Page 10: ...SPECIFICATIONS 186 MM159 6 94 1Ć2 ...

Page 14: ...OPERATION 186 MM159 6 94 2Ć2 ...

Page 84: ...MAINTENANCE 186 MM159 6 94 3Ć48 ...

Page 86: ...APPENDIX 186 MM159 6 94 4Ć2 ...

Page 88: ...APPENDIX 186 MM159 6 94 4Ć4 ...