MAINTENANCE

3Ć13

186 MM159 (6–94)

LPG FUEL TROUBLESHOOTING

Problem

Cause

Remedy

Engine will not start

Out of fuel

Replace fuel tank with full one

Service valve opened too

Close valve and reopen slowly

quickly – engaging safety valve

Plugged fuel filter

Replace filter

Kinked or restricted fuel line

Straighten or replace fuel line

Engine out of tune

Replace spark plug

LPG module failure

Replace module

Fuel lock valve failure

Repair or replace fuel filter lock

Regulator failure

Repair or replace regulator

Engine runs unevenly or

Wrong type of fuel tank –

Replace vapor withdrawal tank

lacks power

liquid withdrawal tank

with vapor withdrawal tank

Plugged fuel filter

Replace filter

Kinked or restricted fuel line

Straighten or replace fuel line

Engine out of tune

Replace spark plug

Restricted air filter

Clean or replace air filter element

Regulator maladjusted

Adjust regulator

ELECTRICAL SYSTEM

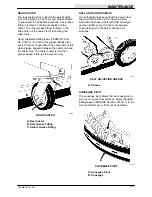

SPARK PLUG

Clean or replace and adjust spark plugs after

every 100 hours of operation. A wire gauge is

best for checking the spark plug gap. A flat gauge

should not be used unless the electrode surfaces

have been dressed with a small file to get parallel

surfaces between the center and side electrodes.

Set the spark plug gap by bending the side

electrode. All spark plugs, new or used, should

have the gaps checked and reset if necessary.

A

B

C

D

01471

GAPPING THE SPARK PLUG

A. Spark Plug

B. Center Electrode

C. Side Electrode

D. Gapping Tool

The proper spark plug gap is 0.023 to 0.028 in

(0.58 to 0.71 mm) for gasoline, and 0.016 to

0.020 in (0.41 to 0.51 mm) for LPG engines.

To get good performance from the spark plugs,

follow these steps when installing the plugs.

1. Clean the spark plug seat in the cylinder

head.

2. Use a new seat gasket and screw the plug

in by hand.

3. Tighten the spark plugs to 22 to 28 ft lb

(30 to 38 Nm) with a socket wrench of the

correct size.

IGNITION SYSTEM

The engine ignition system is the breakerless

type. The ignition system needs no regular

maintenance. The magnet-to-ignition module gap

is 0.012 to 0.016 in (0.30 to 0.41 mm). When

adjusting, tighten module screws to 32 in lb

(3.5 Nm).

STARTER

The starter motor brushes must be inspected after

every 400 hours of operation.

Summary of Contents for 186

Page 1: ...186 MM159 Rev 05 12 95 Operator Manual ...

Page 10: ...SPECIFICATIONS 186 MM159 6 94 1Ć2 ...

Page 14: ...OPERATION 186 MM159 6 94 2Ć2 ...

Page 84: ...MAINTENANCE 186 MM159 6 94 3Ć48 ...

Page 86: ...APPENDIX 186 MM159 6 94 4Ć2 ...

Page 88: ...APPENDIX 186 MM159 6 94 4Ć4 ...