MAINTENANCE

186 MM159 (6–94)

3Ć6

LUBRICATION

ENGINE

Check the engine oil level daily. Change the

engine oil after every 25 hours of operation. Use a

straight SAE 30-weight, API class SF engine oil. If

multiviscosity oil is used, oil consumption and

combustion deposits will increase.

Using other than service class SF oil or extending

oil change intervals could cause engine damage

not covered by the engine warranty.

The engine oil capacity is 1 qt (0.95 L).

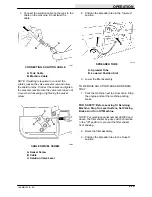

DRIVE CHAINS

The two wheel drive chains propel the machine.

They should be lubricated with a penetrating-type

spray lubricant after every 100 hours of operation.

A

B

C

D

E

03139

WHEEL DRIVE CHAIN

A. Drive Chain

B. Tire

C. Differential

D. Grease Fitting

E. Drive Sheave

DIFFERENTIAL

The differential drives the front wheels. The

differential has one grease fitting located on the

drive shaft inside the drive sheave. Lubricate the

differential every 100 hours of operation with

Lubriplate EMB grease (TENNANT Part No.

01433–1).

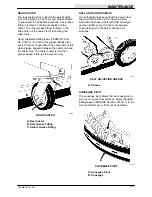

BRUSH ARM PIVOTS

The brush arm pivots on a stub shaft on each side

of the machine. Each of the stub shafts are fitted

with a grease fitting. Apply Lubriplate EMB grease

(TENNANT Part No. 01433–1) to the grease

fittings after every 50 hours of operation.

A

02341

LEFT SIDE BRUSH ARM PIVOT GREASE

FITTING

A. Grease Fitting

SIDE BRUSH GEAR BOX

The side brush gear box drives the side brush. It

is lubricated with SAE 90 weight gear lubricant.

Check the fluid level after every 400 hours of

operation. Remove the breather and fill the gear

box to within 0.25 in (6 mm) of the top if needed.

A

B

03144

SIDE BRUSH GEAR BOX

A. Side Brush Gear Box

B. Breather

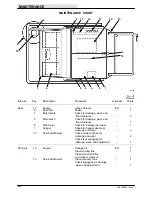

Summary of Contents for 186

Page 1: ...186 MM159 Rev 05 12 95 Operator Manual ...

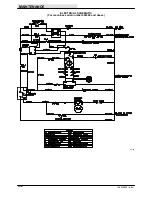

Page 10: ...SPECIFICATIONS 186 MM159 6 94 1Ć2 ...

Page 14: ...OPERATION 186 MM159 6 94 2Ć2 ...

Page 84: ...MAINTENANCE 186 MM159 6 94 3Ć48 ...

Page 86: ...APPENDIX 186 MM159 6 94 4Ć2 ...

Page 88: ...APPENDIX 186 MM159 6 94 4Ć4 ...