33

98-01504-ENUS R2

Aeros 9040 Field Computer

ADDITIONAL IMPLEMENT OPTIONS

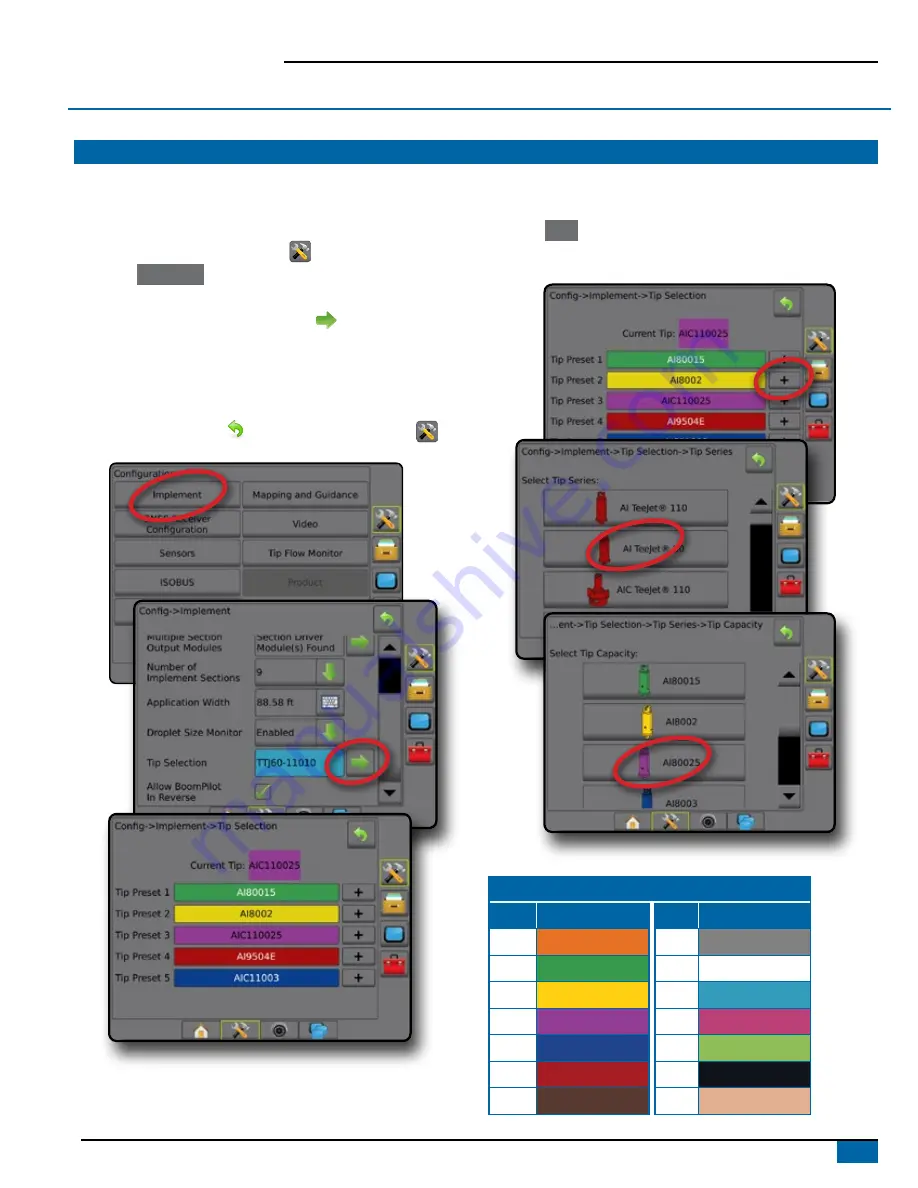

TIP SELECTION

When the system includes a Pressure Sensor Interface Kit (PSIK), Tip

selection is used to select the type of sprayer tip (series and capacity)

for determining droplet size information.

1. Press CONFIGURATION side tab

.

2. Press

Implement

.

◄Current tip section is shown in the information box

3. Press Tip selection NEXT PAGE arrow .

4. Select from:

►Tip preset 1-5 – selects up to five (5) tips for quick recall, and

selected the current tip for determining droplet size information

►Current tip – displays the current tip

5. Press RETURN arrow or CONFIGURATION side tab

to

return to the main Configuration screen.

Preset

Tip presets allow saving of up to five tips for quick recall.

1. Press

+

.

2. Select a TeeJet tip series.

3. Select tip capacity.

Tip Sizes and Associated Colors

Established Tip Capacities and Colors

Size

Color

Size Color

01

Orange

06

Gray

015

Green

08

White

02

Yellow

10

Light Blue

025

Purple

12

Telemagenta

03

Blue

15

Light Green

04

Red

20

Black

05

Brown

30

Beige