SYNCHRO EXCITE Class & Trend: Service & maintenance manual - rev. 2.0

Page 3.11

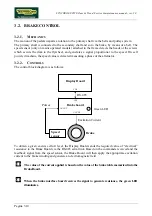

The electromagnetic field produced by the winding and the rotation of the disk will induce eddy

currents in the disk itself, giving rise to a force that tends to brake its motion. This generates the

exercise resistance.

A higher brake excitation signal will produce a correspondingly higher exercise resistance. In

addition, for a given value of brake excitation, a higher speed of disk rotation will produce a

correspondingly higher exercise resistance.

Due to the eddy currents, energy is dissipated on the brake disk in the form of heat.

The Brake Board effects an open loop control of the brake, with no provision for regulating the

value of resistance produced but only uses the brake table memorized into the Brake Board.

The precision of the braking system has a tolerance of

±

10%.

During the movement, the speed sensor detects the heads of the brake disk fixing screws, and

produces a speed feedback signal that is sent to the Brake Board, on the mains operated machines.

On the self powered machines, the speed signal comes directly from the measure of an alternator

phase.

If the Brake Board does not receive a speed signal, which indicates that an exercise session is in

progress, the machine will not produce any resistance.

During the movement, the Brake Board monitors for possible malfunctions. The errors which can

occur are:

Error Code

Description

1

OVERHEATING:

this condition occurs when the temperature detected by

the sensor on the circuit board exceeds 90°C.

2

OVERCURRENT:

this condition occurs when the Brake Board detects an

excessive amount of current being sent to the winding.

8

OVERVOLTAGE:

this condition occurs when the +12 Vdc voltage goes

above 13.7 Vdc (only on the 500, 700 and 700WTV models).

16

SOLENOID OVERHEATING:

this condition occurs when the NTC,

connected in series with the solenoid, detects a temperature higher than 140°C

and opens the circuit.

32

EPROM

: SW error on the Brake Board (braking table).

128

REFERENCE VOLTAGE FAULT:

this error condition occurs when the

calibration parameter stored in the Brake Board is incorrect.

In the case of error 128, the machine remains fully functional, but the braking resistance produced

will not correspond to the value entered on the display. In all other cases, the Brake Board

interrupts the supply of current to the brake, the green LED changes from being steadily on to

blinking and sends an error message to the Display Board which displays the “THE EQUIPMENT

IS BLOCKED (COM)” message.

Summary of Contents for Synchro Excite 500

Page 1: ...SERVICE MAINTENANCE MANUAL REV 2 0 ...

Page 2: ......

Page 4: ......

Page 48: ...SYNCHRO EXCITE Class Trend Service maintenance manual rev 2 0 Pagina 4 6 LIBYA DVB T ...

Page 50: ......

Page 201: ......