2-3. Operation Panel

2-46

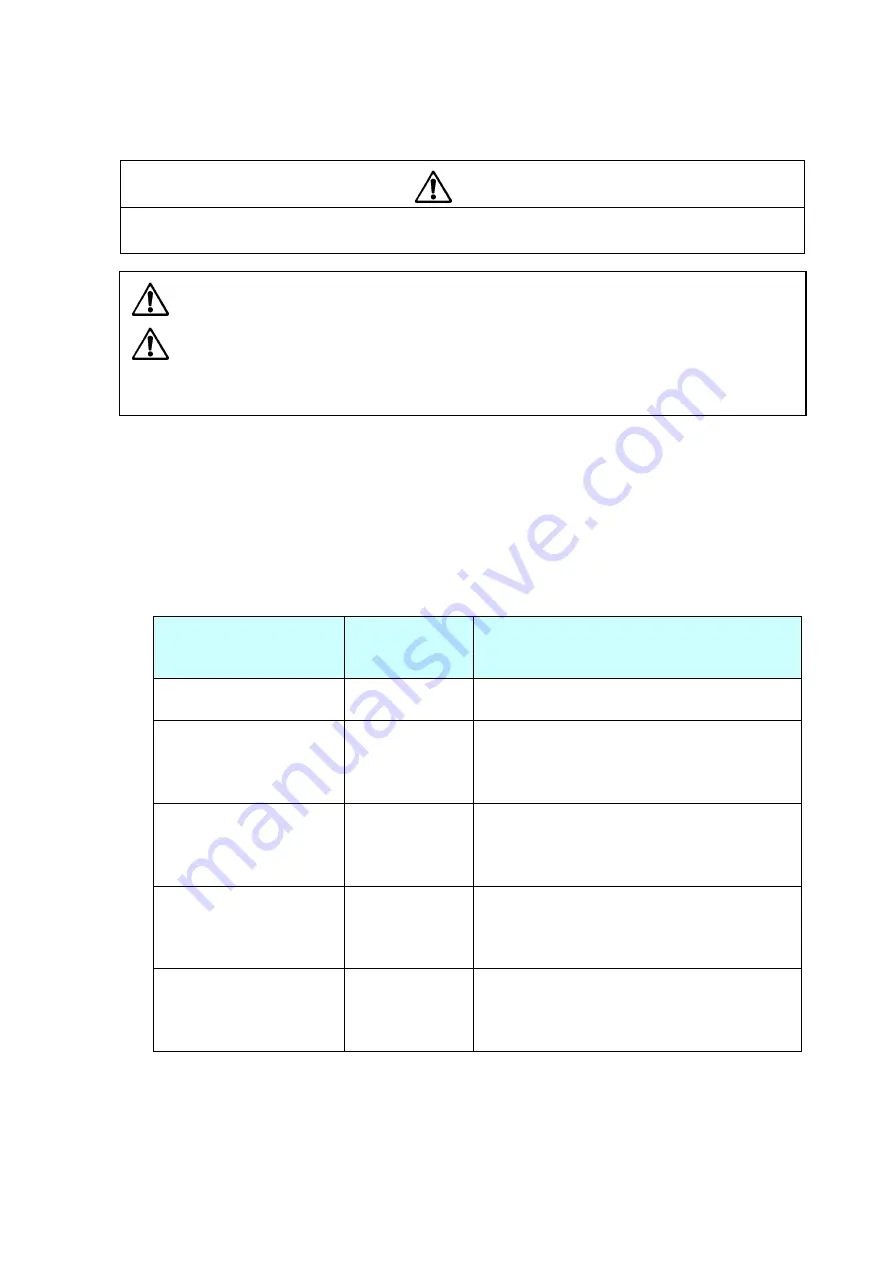

(3) How to change the settings in Factory mode

-

In Factory mode, DO NOT change the factory-set values unless you need to change

them, since there are essential items related to printing accuracy, etc.

- Do not turn OFF the power of the printer until you finish the adjustment. If it is

turned OFF, you need to repeat the adjustment from the beginning.

- The value adjusted here is retained until you change it with the same

procedure. Even if you perform initialization by selecting “Test Mode” main

menu, “Factory Default” submenu and “Yes”, the changed value is not

returned to the initial value set at the factory.

(3-1) Submenu table in Factory mode

The following table shows the submenus of “Factory Setup” main menu.

*1 “[Factory Mode Settings Menu name]” in “Submenu Name” column shows the name

that will be printed in “Factory Mode Settings”. (Refer to “

(2) How to print the Factory

Mode Settings menus

”.)

*2 “+” shows that the object electrically moves forward/rightward. “-“ shows that the object

electrically moves backward/leftward. 8 dots correspond to 1 mm (203 dots correspond

to 1”).

Submenu Name

[Factory Mode Settings

Menu name]

Adjustable Value

(Default Value)

Description

Sens Vol Adj

Displays the level of each media sensor.

Init Fix-Thru

Performs calibration of the transparent sensor

sensitivity (fixed type). For details, refer to “

3-6-1

(2) Sensor sensitivity adjustment (Factory

mode)

” in Chapter 3.

Init Fix-Refl

Performs calibration of the reflective sensor

sensitivity (fixed type). For details, refer to “

3-6-1

(2) Sensor sensitivity adjustment (Factory mode

”

in Chapter 3.

Init Adj-Thru

Performs calibration of the transparent sensor

sensitivity (adjustable type). For details, refer to

“

3-6-1 (2) Sensor sensitivity adjustment (Factory

mode

” in Chapter 3.

Init Adj-Refl

Performs calibration of the reflective sensor

sensitivity (adjustable type). For details, refer to

“

3-6-1 (2) Sensor sensitivity adjustment (Factory

mode

” in Chapter 3.

Caution

Summary of Contents for 7010

Page 1: ...User Guide 7010 Thermal Printer 7010 7010 300 7010R Maintenance Manual 7010 Series ...

Page 2: ...ii Copyright 2010 by DASCOM Europe GmbH ...

Page 5: ...CHAPTER 1 SPECIFICATIONS ...

Page 17: ...CHAPTER 2 OPERATING PRINCIPLES ...

Page 75: ...CHAPTER 3 DISASSEMBLY AND MAINTENANCE ...

Page 133: ...CHAPTER 4 TROUBLESHOOTING ...

Page 155: ...5 6 DRAWING NO 1 General Assembly Rev 0 For 7010 7010 300 ...

Page 168: ...5 19 DRAWING NO 4 SA Front Tension Arm Rev 0 For 7010 7010 300 4 1 4 2 4 4 4 3 4 5 4 6 ...

Page 174: ...5 25 DRAWING NO 6 SA Frame Ribbon R Rev 0 For 7010 7010 300 6 2 6 1 6 4 6 3 ...

Page 194: ...5 45 DRAWING NO 12 SA Front Center Rev 0 For 7010 7010 300 12 4 12 3 12 2 12 1 12 4 ...

Page 197: ...5 48 DRAWING NO 13 SA Front Right Rev 0 For 7010 7010 300 13 3 13 2 13 1 ...

Page 200: ...5 51 DRAWING NO 14 Unit PCB Rev 0 For 7010 7010 300 14 5 14 7 14 4 14 1 14 2 14 3 14 6 ...

Page 208: ...5 59 DRAWING NO 1 General Assembly Rev 0 for 7010R ...

Page 224: ...CHAPTER 6 CIRCUIT DIAGRAMS ...

Page 227: ...6 4 Inter Connection Main PCB 1 15 7010R 01 23415 16 7 89 1 1 11 8 01 5 9 9 15 8991A 89 7010R ...

Page 246: ...6 23 Circuit Diagram Rewinder PCB 7010R 01 2 3 4 56 7 8 9 5 9 28 6 9 ...

Page 247: ...Appendices APPENDICES ...

Page 250: ...Appendices B Mounting Diagrams AP 4 B Mounting Diagrams B 1 Main PCB Main PCB Parts side ...

Page 252: ...Appendices B Mounting Diagrams AP 6 Power Supply PCB Solder side ...

Page 254: ...Appendices B Mounting Diagrams AP 8 B 5 Connect PCB 7010 7010 300 B 6 Rewinder PCB 7010R ...