operation

2

3

Synrad

Firestar i401

operator’s manual

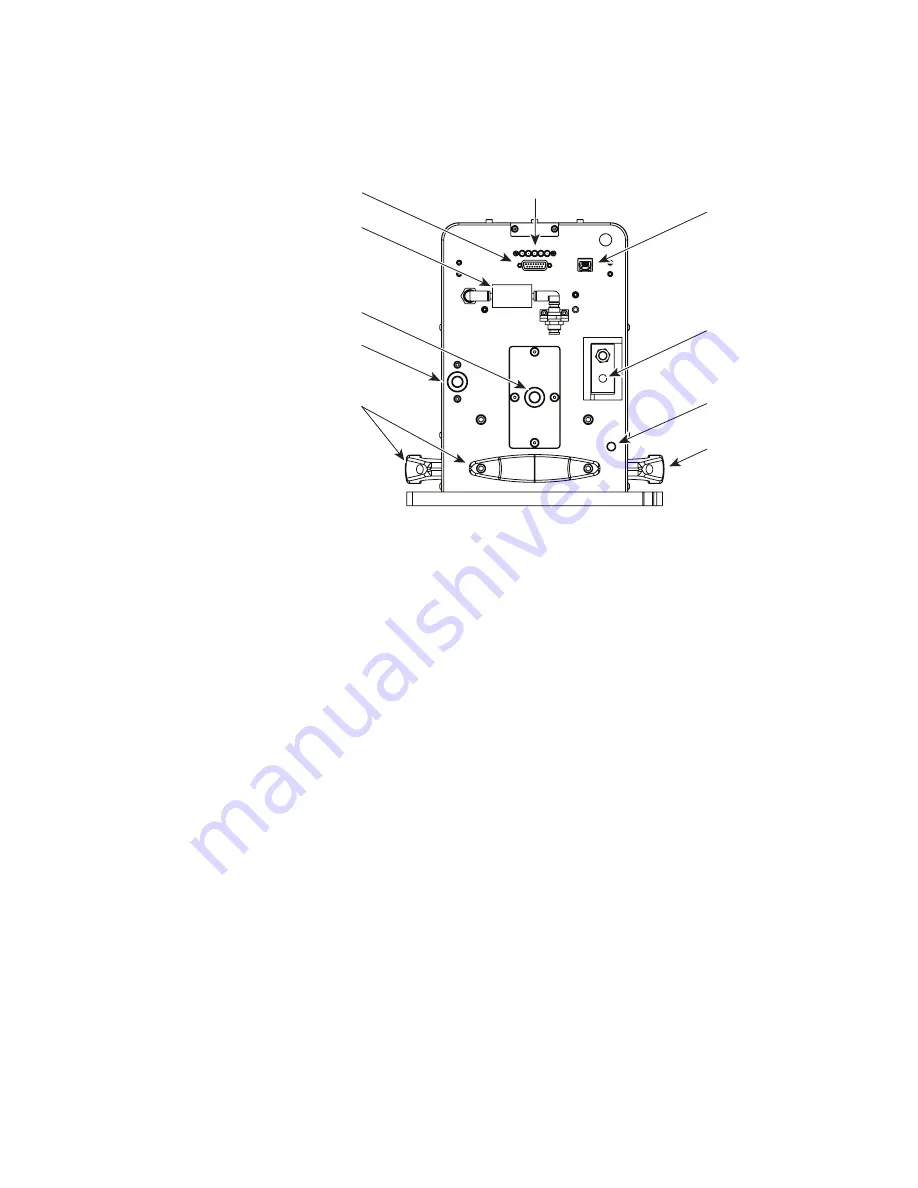

Controls and indicators

Figure 2-2

Firestar i401 rear panel controls and indicators

5

User I/O

Connector – provides a connection point for auxiliary output power, as well as input and

output signals. Refer to the Technical Reference chapter for pinouts and signal descriptions.

6

Gas Purge

Port/Assembly – provides a low pressure nitrogen (or pure air) connection to prevent dust

and debris from damaging electronic or optical components inside the housing.

7

WATER IN

Port – provides inlet connection for Firestar’s cooling system using straight 1/2-inch fit-

tings. The cooling kit contains 90° tubing adaptors for both 1/2-inch and 12-mm cooling tubing.

8

WATER OUT

Port – provides outlet connection for Firestar’s cooling system using straight 1/2-inch

fittings. The cooling kit contains 90° tubing adaptors for both 1/2-inch and 12-mm cooling tubing.

9

Lifting Handles – allow you to safely lift and move the laser. After laser installation, all three handles

can be removed if additional clearance is necessary.

10

GND

(–) Terminal – M10 × 1.5 threaded stud provides connection point for negative (ground) side

of the 48 VDC power supply.

11

48V POWER

Terminal Block – re48 VDC from the 48 VDC power supply. Fasten the posi-

tive

DC Power Cable

using the supplied M10 × 1.5 bolt at the indicated connection point.

12

Ethernet

Port – provides the connection point for a TCP/IP web-based interface between your com-

puter or network and the i401 laser.

INT

TMP

RDY

WATER

OUT

GAS PURGE

12

4

7

8

6

5

9

10

11

9

WARNING

Do not remove water fittings!

Do not lift or pull on water fittings!

This may cause misalignment or water leaks.

If a water leak is discovered, please contact

Synrad customer service immediately.

USER I/O

ETHERNET

Clean and

Dry Air or

N

2

only

SHT LASE

DC POWER

48 VDC

0 VDC

WATER

IN