44

Operation & Maintenance Manual

Cyclo® HBB

Cyclo® HBB

3

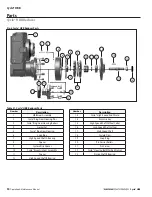

When reinserting the

eccentric

bearing assembly

, use only a wooden or

hardrubber mallet to tap it into place

4

Insert the

top Cycloid disc

so that the code engraved on its surface is 180° opposed

to the corresponding etched code on the

lower Cycloid disc

5

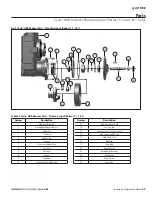

If the Cyclo® portion of the HBB unit is grease lubricated, refill the reduction

components with the amount specified in

Grease Quantities

section of this manual;

or,

fill to 33%-50% of the space around the reduction mechanism and bearings of

single reduction units, and 33%-50% of the space around the reduction mechanism

of both the first and second stage of double reduction units

If the Cyclo® portion of the HBB unit is oil lubricated – do not add any grease

during the reassembly process

6

When reassembling the HBB gear housing onto the Cyclo® reduction stage, ensure

that the

carrier pins

are inserted and aligned with the corresponding bores of the

rollers

Cyclo® Portion Disassembly/Assembly

Cyclo® Reassembly Procedure

Eccentric

Bearing

Code on

upper disc

Code on

lower disc

X

X

180º

Summary of Contents for Cyclo HBB

Page 1: ...0 7 6 0 1 6 0 0 0 3 H B B O M2 0 1 8...

Page 27: ...MA X MI N...