Cyclo® HBB

Operation & Maintenance Manual

9

Cyclo® HBB

Installation onto Driven Shaft

Using Taper-Grip® Bushing

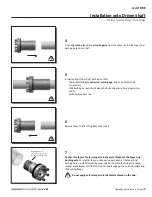

4

Clean all

grease, oil

and/or

anti-seize paste

from the driven shaft Slide Taper-Grip®

bushing onto driven shaft

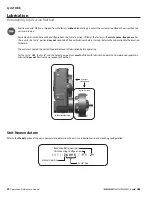

5

Inspect and test Taper-Grip® Bushing on shaft

• Check shaft for

burrs, corrosion, or warpage

Repair or replace shaft

as necessary

• Slide bushing back and forth along shaft, checking for surface irregularities

and fit

• Verify bushing bore size.

6

Remove Taper-Grip® Bushing from driven shaft

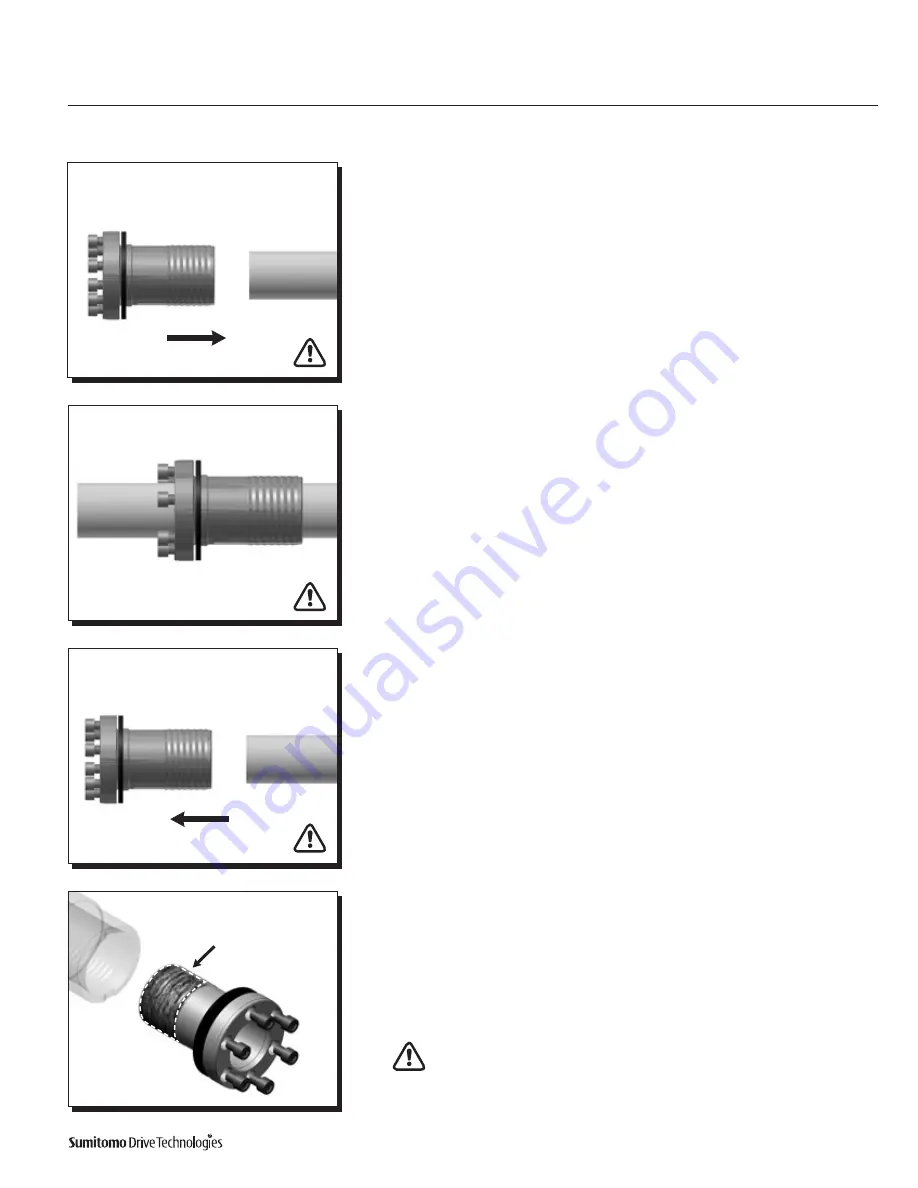

7

Apply a thin layer of anti-seize paste to the male threads of the Taper-Grip®

bushing only

Ensure that the anti-seize paste does not enter the Taper-Grip®

bushing bore Carefully thread the Taper-Grip bushing into the hub of the speed

reducer or gearmotor until the thrust collar solidly engages the unit hub surface and

the bushing flange

Do not apply anti-seize paste to the female threads in the hub

Apply thin layer of

anti-seize paste to male

threads of bushing only

Summary of Contents for Cyclo HBB

Page 1: ...0 7 6 0 1 6 0 0 0 3 H B B O M2 0 1 8...

Page 27: ...MA X MI N...