Cyclo® HBB

Operation & Maintenance Manual

17

Cyclo® HBB

Torque Arm Installation

T-Type Torque Arm

T-Type Torque Arm

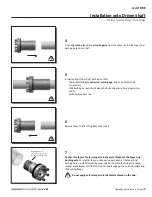

Fig 2 T-Type Torque Arm Parts

Table 6 Sumitomo Supplied T-Type Torque Arm Parts

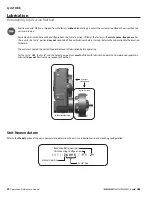

Fig 3 Customer Supplied T-Type Torque Arm Parts

Table 7 Recommended Threaded Rod Diameter

1

2

1

4

3

Item Number

Description

1

Mounting Hardware (Bolts, Washers, Nuts)

2

T-Bracket

3

Rubber Bushings

4

Washers

Cyclo® HBB

Rod Diameter

Size

(Minimum Grade 8.8 Steel)

Z

M12

A

M16

B

M20

C

M24

D

M24

E

M30

Threaded Rod

Nuts

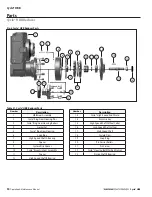

Mounting

Bolt

Mounting

Bolt

T-bracket

HBB

Bolt Tightening Torque

Size

Size

ft•pound

N•m

Z

M12

40-46

54-62

A

M16

92-130

125-176

B

M16

92-130

125-176

C

M20

191-270

259-366

D

M24

330-466

447-632

E

M30

655-923

888-1251

T-Type Torque Arm Installation Procedure

1

Attach the T-Bracket to the Cyclo® HBB using the supplied mounting hardware.

Tighten mounting bolts according to the values listed in this table:

Table 8 T-Type Torque Arm Bolt Torques

Summary of Contents for Cyclo HBB

Page 1: ...0 7 6 0 1 6 0 0 0 3 H B B O M2 0 1 8...

Page 27: ...MA X MI N...