Operation & Maintenance Manual

7

Cyclo® HBB

Cyclo® HBB

Installation Notes

Installation Precautions

• Do not use the reducer/gearmotor for specifications

other than those shown on the nameplate or in the

manufacturing specification documents Personnel

injury and/or equipment damage may occur

• Do not place combustible material on or around

the unit; fire may occur

• Do not place any objects around the unit that will

prohibit proper ventilation Inadequate ventilation

may lead to high unit temperature and/or fire

• Do not step on or hang from the unit. Excessive

weight may cause component breakage leading to

personnel injury and/or equipment damage

• Do not touch the shaft, keyway, or motor fan with

bare hands; injury may occur

• For applications in which lubricant leaks could

adversely affect operations (i.e., package handling,

food processing), place an oil pan below the unit to

protect against contamination that may occur if oil

seals become damaged or worn

Installation Location

Ambient Temperature Range: 14 – 104°F (-10 – 40°C)

Ambient Humidity: 85% or less

Altitude: 3,280 feet (1,000 m) or less

Atmosphere: The location should not contain corrosive gas,

explosive gas, or steam The location should be free of dust and

well ventilated

Location: Indoor – free of dust and water

Consult Sumitomo when the unit will operate in conditions other

than those specified above Special unit modifications may be

required

Units manufactured according to customer specified application

requirements (i e outdoor modifications, high-temperature

modifications) are designed to operate within the specified

environment

Install the unit so inspection and/or maintenance procedures may

be easily performed Install all units that are not shaft mounted

on a sufficiently rigid base

Installation Angle

You must mount the unit horizontally

Please consult Sumi-

tomo if the unit needs to be installed in a position other than

horizontal

If the unit was manufactured for a mounting position other than

horizontal,

do not mount it in a position other than the one

specified

Horizontal is the shaft orientation for standard units Consult

Sumitomo for shaft directions other than horizontal

• Do not remove the eye-bolt from the motor. Should

you need to remove the eye-bolt for any reason,

install a replacement bolt in the tapped hole to

prevent water from entering the motor

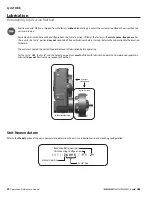

Severe Loading Conditions

For applications with severe vibration and/or frequent starts and

stops, Sumitomo recommends the use of high-strength bolts of

Grade 8 8 (or greater) to mount the reducer/gearmotor

Installation onto the Driven Machine

• Before mounting the reducer/gearmotor to the

machine, verify the appropriate/desired rotation of

the machine Differences in the rotational direc-

tion may cause personnel injury and/or equipment

damage

• If a key is attached to the keyed hollow bore, tem-

porarily remove the key if the unit is not coupled to

the driven machine and you wish to run the unit

• Before operating the unit, ensure that all safety

guards around the rotating components are

in-place and secure Failure to do so may result in

personnel injury

• When joining the reducer or gearmotor to the load,

ensure that the center alignment, belt tension, and/

or parallelism of the coupling device are within the

coupling manufacturer’s established recommenda-

tions For applications with a belt, ensure that the

belt is properly tensioned to the manufacturer’s

specification, and the bolts securing the pulley

and couplings are sufficiently tightened Failure to

follow these precautions may result in personnel

injury and/or equipment damage

Summary of Contents for Cyclo HBB

Page 1: ...0 7 6 0 1 6 0 0 0 3 H B B O M2 0 1 8...

Page 27: ...MA X MI N...