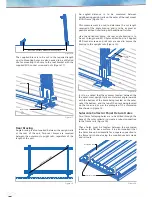

M10 socket screw

(& washer)

M6 TS self-drilling

screw

Angle bracket

(right)

Angle bracket

(left)

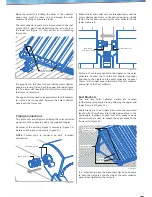

Figure 26

M6 TS self-drilling

screw

Angle brace

M10 socket screw

(& washer)

Rail nut

Collector

Figure 25

Angle Bracket Fastening

Angle brackets are required to secure the top of the solar

collectors to the upper frame rail. These angle brackets

are to be created from the supplied angle bracing by

cutting to a length of approx. 85mm (cut on site).

When both rail nuts are fastened, M6 TS self-drilling

screws are needed to screw the brace to the solar

collector frame.

Two to three screws can be used per brace, with

placement being crucial as to not damage or penetrate

the solar collector flashing or evacuated tubes. The TS

screws are used to drill through the angle brace and to

fasten only to the frame of the solar collector (Figure 25).

Securing a brace at one end will assist in aligning the solar

collector panels and keeping the frame square and will

also stop the solar collector panels from unintentional

movement.

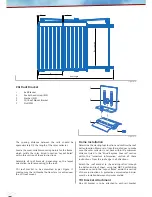

Electronic Controller Position (Indoor)

The electronic controller should be mounted on an inside

vertical surface, where it is protected from moisture and

direct sunlight. A wall in the kitchen or laundry is ideal.

Electronic Controller Position (Outdoor)

The electronic controller should be mounted on an

outside vertical surface, where it is sheltered from direct

sunlight and weather. A wall under the eaves is ideal.

The electronic controller should be mounted at chest

height in a position where it can be easily accessed.

The electronic controller will require a 240V, 10A earthed

power point.

IMPORTANT NOTE

The controller is factory programmed to the correct

settings. These settings must not be altered.

To ensure frost protection the power must remain connected

to the electronic controller and circulation pump.

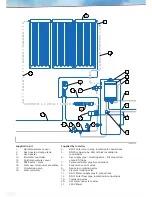

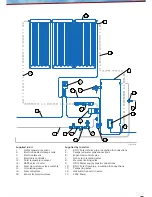

Installation Procedure

The mains power supply lead, circulation pump power

lead, hot temperature sensor lead and cold temperature

sensor lead are connected to the electronic controller.

The system installation diagrams shown in Figure 29 and

Figure 30 detail the general arrangement of components,

plumbing and wiring.

Please refer to the manufacturer’s instructions for the

electronic controller installation and wiring connection

details. Failure to follow the manufacturer’s instructions

may cause failure of the electronic controller and will

void the warranty.

IMPORTANT NOTE (INDOOR CONTROLLER)

The second storage sensor TT and electric boost heating

element are not connected to the electronic controller.

INSTALLATION OF ELECTRONIC CONTROLLER

A 10mm hole (dia.) must also be created on site on the

appropriate face of each bracket (Figure 26).

Each solar collector attached to the mount requires both

a left and right bracket to affix the panel to the unit.

The angle brackets are to be pushed hard against both

the outer of the framing rail and also the inside face of

the solar collector frame, then tightly fastened to the

back of the frame rail using the supplied M10 socket

screws and rail nuts.

When all brackets have been fastened into place, M6 TS

self-drilling screws are used to drill through the bracket

and into the solar collector frame, subsequently fastening

the panels to the top rail (Figure 26).

The area of the solar collector frame to drill through is

slight and the installer must be sure not to damage the

solar collector when fastening.