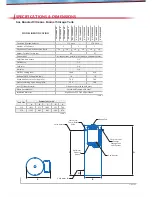

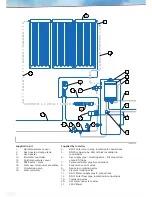

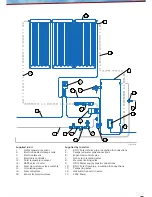

Number of Collectors

2

3

DN 15 pipes

40m

30m

Table 13

Water Supply

Approved pressure limiting valves rated at 500kPa are

required if the mains water supply pressure exceeds

500kPa.

The gas booster will not achieve the maximum rated flow

if the mains water supply pressure is below the minimum

supply pressure specified for the gas booster in Table 7

“Gas Boosters Specifications”. The system will operate at

lower pressures but will deliver hot water at lower flow

rates.

Water chemistry and impurity limits are specified under

“Water Quality” in the “Important Information” section

of these instructions. Metropolitan water supplies

generally meet these requirements. Please contact the

relevant water supply authority or have the water tested

if uncertain about the water supply quality.

If necessary, a suitable filter or water softener should be

fitted in the mains water supply to achieve the required

water quality.

For locations with high sediment levels in the water

supply, the hot water storage tank should be flushed at

regular intervals. Stratco recommend that a drain cock

is fitted at the cold water inlet to the hot water storage

tank.

Water Pipes, Valves & Fittings

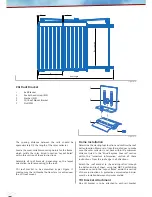

All hot water pipes must be insulated with thermal

lagging such as Polyethylene foam to reduce heat loss

and maximise performance of the solar hot water heating

system.

All pipe sizes should conform to AS/NZS 3500 except

collector flow and return pipes.

Solar collector flow and return pipes should be 15mm

copper tube to withstand the high pressures and

temperatures that occur. Maximum recommended total

lengths for the cold water flow and hot water return

pipes are shown in Table 13.

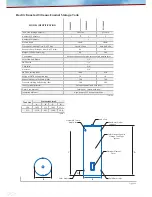

The pressure and temperature relief (P&TR) valve is a

safety device and must be fitted to the hot water storage

tank. The P&TR valve supplied is rated at 10.0kW,

which must exceed the thermal load applied to the hot

water storage tank. For gas boosted solar hot water

heater systems, the thermal load is applied by the solar

collectors only. The gas booster does not apply thermal

load to the hot water storage tank.

A cold water expansion control valve (ECV) rated at

700kPa must be fitted to the cold water supply of the hot

water storage tank. This will reduce hot water discharge

resulting in wear of the P&TR valve.

Approved pressure limiting valves rated at 500kPa must

be fitted if the mains water supply pressure exceeds

500kPa.

A combination non-return/isolating valve and strainer is

fitted to the cold water supply of the hot water storage

tank.

Gas boosters for Stratco Solarcore

TM

hot water heating

systems are preset to deliver hot water at 70°C in

accordance with plumbing regulations. A temperature

limiting device, such as thermostatic mixing or tempering

valves, must be fitted to limit the hot water temperature

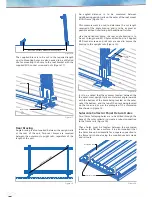

For vitreous enamel hot water storage tanks, allow a

clearance of one cylinder height above the hot water

storage tank to allow inspection and replacement of the

sacrificial anode.

Gas Booster Location

The gas booster is designed for outdoor installation only,

and must be located in a position where wind and natural

convection will disperse gas leakage and combustion

products.

The gas booster must be mounted on a vertical surface

with the water and gas connections underneath. In most

installations the gas booster is mounted directly on the

hot water storage tank.

If the gas booster is not mounted on the hot water

storage tank, ensure that the wall or structure on which

it will be mounted is capable of supporting the weight

of the gas booster and associated plumbing. The weight

of the gas booster models is specified in Table 7 “Gas

Boosters Specifications”.

The location of the gas booster terminal flue must be in

accordance with AS 5601 Figure 5.3.

Refer to AS 5601 for specific requirements in relation to

gas boosters installed on elevated structures or under

floors.

The gas booster will require a gas supply as outlined

in the “Gas Supply” section of these instructions and a

240V, 10A earthed weather proof power point.

Gas Supply

The gas meter and regulator must be rated for the

maximum flow of the gas booster in addition to all

other gas appliances on the premises. Please refer to

the manufacturer’s instructions for the gas booster to

determine maximum gas consumption and required gas

pressure.

It is the installers responsibility to ensure gas meter,

regulator and pipework are functional, sized correctly

and rectify as necessary.

Gas pipe sizing must conform to the sizing chart in AS

5601. If pipe sizes are not sufficient, the gas booster will

not achieve full heating performance.

An approved full flow isolation valve and disconnection

union must be fitted to the gas inlet of the gas booster.