< /-

Set

< /+

MM 4

SET

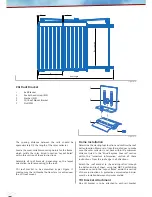

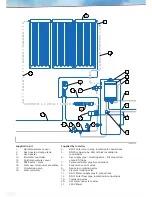

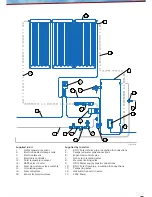

Figure 31 - Indoor Controller

COMMISSIONING

Filling the System

Ensure building occupants are warned to stay clear of

the solar hot water heating system components and pipe

work as hot water or steam may be discharged.

For gas boosted Stratco Solarcore

TM

hot water heating

systems, switch off the electric power supplies to the gas

booster and electronic controller and close the isolating

valve on the gas supply to the gas booster.

For electric boosted Stratco Solarcore

TM

hot water heating

systems, switch off the electric power supplies to the

electric heating elements and electronic controller.

Open the hot water tap at the closest sink or basin. Open

the isolating valve on the cold water supply to the hot

water storage tank. The entire solar hot water heating

system will now fill with cold water and expel air through

the hot water tap.

Close the hot water tap at the sink or basin when water

flows continuously without air bubbles or air bursts. Open

the next closest hot water tap and close when water flows

continuously without air bubbles or air bursts. Continue

opening and closing hot water taps until all pipes have

been purged of air.

Check all connections for leaks and tighten or repair if

necessary. Operate the easing gear on the ECV and P&TR

valves on the hot water storage tank to ensure the valves

are functional.

Circulating Pump & Electronic Controller

Turn on the power supply to the electronic controller

and wait for the controller to complete the initialisation

phase. The circulating pump can then be turned on

manually as follows:

INDOOR CONTROLLER

•

Press the “>/+” button until the display shows AC 1.

•

Press the “SET” button and the word “SET” begins

flashing.

•

Press the “>/+” button until the display shows AC 12.

•

Press the “SET” button again to accept the value and

the word “SET” stops flashing.

•

Press the “>/+” button until the display shows MM 4.

•

Press the “SET” button and the word “SET” begins

flashing.

•

Press the “</-” button until the display shows MM 1.

•

Press the “SET” button again to accept the value and

the word “SET” stops flashing.

•

The LED flashes red/green to show the pump is

running.

•

Press the “</-” button to exit the settings menue,

until “TC” and “TS” are shown in the display.

OUTDOOR CONTROLLER

•

Press and hold the pump button.

The circulating pump should now run continuously. This

can be confirmed by checking the flow meter on the

solar non-return valve assembly. The flow rate must be

adjusted to 1.0LPM by turning the screw and aligning

the bottom fo the float with the 1LPM mark on the flow

meter. If the pump does not operate, check all wiring

and connections to the controller and pump. If the wiring

is correct and the pump still does not operate, turn off

power to the temperature differential controller and

contact your Stratco representative.

When correct pump operation has been confirmed,

return the Indoor Controller to fully automatic mode

using the above procedure and changing the operating

mode “MM” to “4”. Important - do not leave the pump

running in manual mode. Confirm freeze protection and

temperature settings.

IMPORTANT NOTE

The controller is factory programmed to the correct

settings. These settings must not be altered.

Gas Booster

This section applies for gas boosted Stratco Solarcore

TM

hot water heating systems only.

Ensure the isolating valve on the gas supply to the gas

booster is closed. Remove the test point screw on the

gas inlet connection of the gas booster and attach a

pressure gauge.

Turn on the power supply to the gas booster but not the

temperature differential controller. Open the isolating

valve on the gas supply to the gas booster. Ensure the

isolating valve on the cold water supply to the hot water

storage tank is open.

Ensure building occupants are warned to stay clear and

then open all hot water taps.

Operate all other gas appliances at their maximum

gas consumption. The gas pressure gauge should read

between 1.13 and 3.0kPa for Natural Gas and between

2.75 and 3.0kPa for LPG. If the gas pressure is lower,

the gas supply is inadequate and the gas booster will

not achieve full heating performance. It is the installers

responsibility to ensure gas meter, regulator and pipe-

work are funtional, sized correctly and rectified as

necessary.

When correct gas pressure has been confirmed, close

all hot water taps and return all gas appliances to their

original settings.