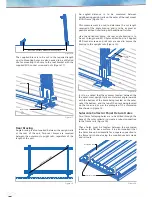

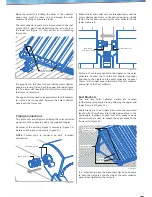

Rafter

Tile Batten

Fixing strap -

Secured with

two Hex head

self-drilling

screws

Fixing strap - Secured

with two Hex head

self-drilling screws

Collector - Secured to strap

with two screws

Collector - Secured to strap with

retaining plates, screws and nuts

Figure 6

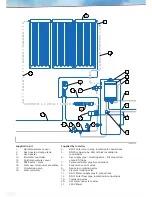

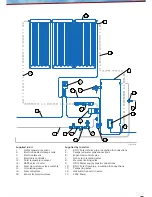

N

45

°

45

°

Latitude

±20

°

Figure 5

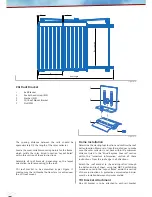

Regulations & OH&S

Before starting installation of the solar collector/s, the

installer should ensure they have read the “Important

Information” section of these instructions and are

familiar with the relevant standards, OH&S regulations

and safety precautions.

It is the builder’s responsibility to ensure the existing

house structure is adequate to take the additional loads

of the SolarCore

TM

Hot Water System.

Installation Procedure

The solar collectors are mounted on a tiled roof using

stainless steel straps that are fastened to the roof battens

as shown in Figure 6.

Protect the gutter from being damaged by ladders, tools

and the solar collectors. Check the condition of the roof

where the solar collectors will be mounted and report

any broken tiles to the owner. Broken tiles in the planned

solar collector location/s should be replaced or swapped

with tiles near the gutter.

Mark the desired position of the bottom stainless steel

straps using a straight edge or plumb line to ensure all

collectors will be horizontal and aligned to each other.

The bottom stainless steel straps should be spaced as

shown in Figure 7.

Remove sufficient tiles from above the tiles supporting

the bottom frame and align the hook on the bottom

stainless steel straps with the markings. Fasten the

bottom stainless steel straps to the roof battens using

two hex head self- drilling wood or metal screws as

shown in Figure 6.

It is important that the correct fasteners are used to suit

the batten material. Incorrect fasteners may become

loose over time, resulting in an unsafe installation.

INSTALLATION PROCEDURE - TILED ROOF

Collector Position

Avoid significant shade from trees or other buildings

falling on the solar collectors three hours before or after

midday. Minor shading from antennas or flues will not

affect solar collector performance.

Mount the solar collectors as close as possible to the hot

water storage tank to minimise pipe runs and heat loss.

Also consider that the hot water storage tank should be

located as close as possible to the most frequently used

hot water outlets to minimise water wastage and heat loss.

Replace the tiles over the bottom stainless steel straps

and ensure they seat correctly. Flash or seal the tiles (if

required).

Raise the solar collector onto the roof and immediately

place it in position with the bottom frame hooked into

the bottom stainless steel straps.

Remove the plastic cover from adjoining sides of all solar

collectors and remove the compression union nipple

from one of the adjoining solar collectors.

Wrap the plastic around the first solar collector tube and

tuck it underneath, to prevent damage from exposure of

unfilled tubes.

Raise the next solar collector onto the roof and

immediately place it in position with the bottom frame

hooked into the bottom stainless steel straps. Slide the

second solar collector against the first and tighten the

compression union.