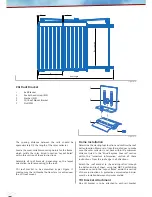

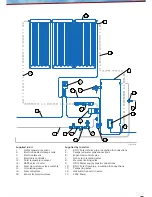

Number of Collectors

2

3

DN 15 pipes

40m

30m

Table 14

It is the electrician’s responsibility to ensure the wiring

to the electric boosted solar hot water heating elements

is capable of withstanding the electrical load. Please

refer to “Electric Boosted Vitreous Enamel Storage Tank”

for power ratings of the electric heating elements.

Water Supply

Approved pressure limiting valves rated at 500kPa are

required if the mains water supply pressure exceeds

500kPa.

Water chemistry and impurity limits are specified

under “Important Information” in these instructions.

Metropolitan water supplies generally meet these

requirements. Please contact the relevant water supply

authority or have the water tested if uncertain about the

water supply quality.

If necessary, a suitable filter or water softener should be

fitted in the mains water supply to achieve the required

water quality. For locations with high sediment levels in

the water supply, the hot water storage tank should be

flushed at regular intervals. Stratco recommend that a

drain cock is fitted at the cold water inlet to the hot water

storage tank.

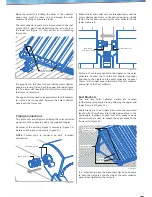

Water Pipes, Valves & Fittings

All hot water pipes must be insulated with thermal

lagging such as Polyethylene foam to reduce heat loss

and maximise performance of the solar hot water heating

system. All pipe sizes should conform to AS/NZS 3500

except collector flow and return pipes.

Solar collector flow and return pipes should be 15mm

copper tube to withstand the high pressures and

temperatures that occur. Maximum recommended total

lengths for the cold water flow and hot water return

pipes are shown in Table 14.

INSTALLATION OF ELECTRIC BOOSTED STORAGE TANK

Regulations & OH&S

Before starting installation of the hot water storage tank

with electric booster, the installer should ensure they

have read the “Important Information” section of these

instructions and are familiar with the relevant standards,

OH&S regulations and safety precautions listed.

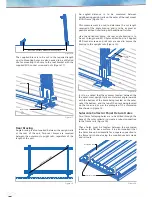

Hot Water Storage Tank Location

The hot water storage tank should be located as close as

possible to the most frequently used hot water outlets

to minimise water wastage and heat loss. Also consider

that the solar collectors should be mounted as close as

possible to the hot water storage tank to minimise pipe

runs and heat loss.

The hot water storage tank has an ingress protection

rating of IPX4 and is suitable for internal or external

installation. For external installation, the hot water

storage tank should be mounted on a concrete base at

least 50 mm thick in accordance with AS/NZS 3500.4

clause 4.5.3, or on well seasoned, evenly spread

hardwood slats at least 25 mm thick.

For internal installations, or where water leakage may

cause property damage, the hot water storage tank should

be installed with an approved safe tray in accordance with

AS/NZS 3500.4 clause 4.4. This will prevent property

damage in the event of a leak and will allow draining of

the hot water storage tank for maintenance.

Ensure the hot water storage tank does not stand on wet

surfaces. The electric boosted hot water storage tank

will require a cold water supply as outlined in “Water

Supply” within this section of these instructions and an

independent 240V power supply installed at the switch

board as outlined in “Electricity Supply” within this

section of these instructions.

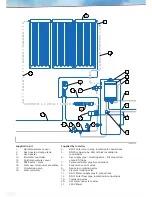

All system components must be located for accessibility.

The hot water storage tank must be accessible without

ladders or scaffolding. Clearance must be provided for

access to and removal of all serviceable parts including

P&TR valve, circulating pump and electric heating

elements. Warning signs and information on rating

plates must be visible.

For vitreous enamel hot water storage tanks, allow a

clearance of one cylinder height above the hot water

storage tank to allow inspection and replacement of the

sacrificial anode.

Electricity Supply

All electric boosted solar hot water heating elements

must be connected to an independent, fused AC 240V,

50 Hz power supply with an isolating switch installed at

the switch board.

Electrical connection must be carried out by a licensed

electrician in accordance with AS/NZS 3000 Electrical

Installations.

The pressure and temperature relief (P&TR) valve is a

safety device and must be fitted to the hot water storage

tank. The P&TR valve supplied is rated at 10.0kW,

which must exceed the thermal load applied to the hot

water storage tank. For electric boosted solar hot water

heater systems, the thermal load is applied by the solar

collectors and the electric heating elements.

A cold water expansion control valve (ECV) rated at

700kPa must be fitted to the cold water supply of the hot

water storage tank. This will reduce hot water discharge

resulting in wear of the P&TR valve. Approved pressure

limiting valves rated at 500kPa must be fitted if the mains

water supply pressure exceeds 500kPa. A combination

non-return/isolating valve and strainer is fitted to the

cold water supply of the hot water storage tank.