Total dissolved solids

< 600mg/litre or ppm

Total hardness

< 200mg/litre or ppm

Chloride

<250mg/litre or ppm

Sodium

<150mg/litre or ppm

Magnesium

<10mg/litre or ppm

Dissolved CO2

<18mg/litre or ppm

Saturation Index (Langelier)

< +0.4 at 65°c

pH level

6.5 to 8.5

Table 1 - Water Quality Limits

present in swimming pool and spa water will result in

corrosion and will void the warranty.

Freeze Protection

The solar collector is protected from damage during

freezing weather conditions by automatically circulating

water from the hot water storage tank.

If the solar collector temperature falls below 10°C, the

circulation pump is activated periodically for brief intervals

(indoor controller only). If the solar collector temperature

falls below 5°C, the circulation pump is activated

continuously.

The collectors have been tested and met the requirements

of AS2712-2007 “Test for Protection against Freezing

- Method B, Level 2”. The collectors lowest working

temperature is -20°C.

It is critical that the automatic freeze protection function

in the indoor controller is active by ensuring the freeze

protection function “AF” is set to “1”. This is the default

setting in the electronic controller. De-activating the freeze

protection function “AF” by setting it to “0” is likely to result

in damage to the solar collector during freezing weather

conditions and will void the warranty.

Stagnation & Overheating

Stagnation occurs when water stops flowing through the

solar collector due to power failure, or when the circulation

pump is switched off. This results in the solar collector

temperature increasing during solar heating conditions,

until the P&TR valve activates and releases hot water or

steam from the system. This is normal and protects the

storage tank from overheating.

The circulation pump is switched off automatically by the

electronic controller if the water temperature exceeds 65°C

in the hot water storage tank or 130°C in the solar collector.

This also results in the solar collector temperature

increasing until the P&TR valve activates and releases hot

water or steam from the system. This is normal during

extended periods of very hot, sunny weather or low hot

water usage, and protects the solar hot water storage tank

from overheating.

The circulation pump is switched on again when the water

temperature falls below 80°C in the solar collector and

below 65°C in the hot water storage tank.

During extended absences in summer it is advisable to

cover the solar collector to avoid overheating the system

and excessive dumping of hot water from the P&TR valve.

Hydrogen Gas Warning

(For vitreous enamel hot

water storage tanks with protective anode):

If the hot water system is not used for two weeks or

more, a quantity of highly flammable Hydrogen gas may

accumulate in the hot water storage tank.

To dissipate this gas safely, it is recommended that a hot

tap is turned on for several minutes or until discharge of

gas ceases. Use a sink, basin or bath outlet but not a dish

washer, clothes washer or other appliance.

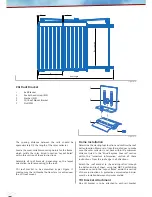

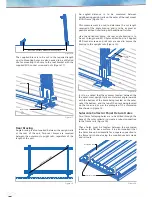

Occupational Health & Safety

Solar collectors are large, bulky items that are generally

installed on the roof of a building. Installers must be

adequately trained and aware of their responsibilities

regarding manual handling and working at heights under

local OH&S regulations.

The installer must take care to warn/protect the building

occupants and public from personal injury which may

result from:

•

Falling tools or materials.

•

Work site hazards.

•

Scalding from hot pipes and fittings or escaping hot

water or steam.

Qualified Installers

The Stratco Solarcore

TM

hot water system must be installed

by licensed plumbing, gas fitting and electrical professionals

that have been trained and authorised by Stratco.

Safety Devices

The hot water system is fitted with the following safety

devices to comply with regulations and ensure ongoing

safe operation.

•

Pressure and temperature relief valve

•

Expansion control valve

•

Pressure limiting valve

•

Non-return valves

•

Tempering valve

It is important that these devices are maintained and

tested/replaced at regular intervals by an Authorised

Stratco installer, as outlined in the “Maintenance” section

of these instructions. Drain lines from the pressure

& temperature relief valve and expansion control valve

should be kept free of blockages.

Water Quality

The water quality from metropolitan water supplies is

generally suitable for the Stratco Solarcore

TM

hot water

heating system. The water quality from bore water

supplies is generally not suitable for the hot water system.

The water quality must meet the limits shown in Table 1

“Water Quality Limits”. Water quality outside of these limits

may cause early failure of the hot water system and will

void the warranty. Please contact the relevant water supply

authority or have the water tested if uncertain about the

water supply quality.

Corrosion

The hot water system must not be used to heat a chlorinated

swimming pool or spa water. The high levels of chloride