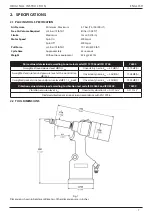

4.2 STROKE ADJUSTMENT

This adjustment is necessary to ensure optimum insert deformation.

It is suggested, therefore, that a test plate with the same thickness

and hole size as workpiece be used.

If deformation is insufficient, the insert will rotate inside the

application. If deformation is excessive, thread distortion will occur

and possibly drive screw fracture.

The stroke is adjusted by the amount the rear casing

86

is screwed

in or out. To shorten stroke, screw in; to lengthen stroke, unscrew the

rear casing but never more than 5 turns from the fully “IN” position

unless dismantling the tool. Adjust until optimum deformation is

obtained.

Lock the stroke set finger

88

into the rear casing.

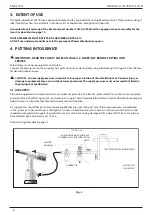

4.3 PRINCIPLE OF OPERATION

•

Connect tool to air supply.

•

Offer up insert, lip first to drive screw. A light pressure will start the motor and automatically thread the insert up

against nose and stop.

•

Insert fastener into application squarely.

•

Fully depress trigger. This will both place insert into the application and reverse it off the drive screw.

Item numbers in

bold

refer to the General Assembly drawing and parts list (pages 18-19).

CAUTION -

do not attempt to force the installation of an insert as this will cause damage to the tool and/or application.

Fig. 3

9

ORIGINAL INSTRUC TION

ENGLISH

Summary of Contents for Avdel 74200

Page 68: ...7 OPĆI SKLOPOVI 7 1 OPĆI SKLOP OSNOVNOG ALATA 74200 12000 68 HRVATSKI PRIJEVOD IZVORNIH UPUTA ...

Page 223: ...223 ПЕРЕВОД ОРИГИНАЛЬНОЙ ИНСТРУКЦИИ РУССКИЙ ...

Page 312: ...7 KOOSTEJOONISED 7 1 KOOSTEJOONIS PÕHISEADE 74200 12000 312 EESTI KEEL ORIGINAALJUHENDI TÕLGE ...

Page 347: ...347 ΜΕΤΑΦΡΑΣΗ ΤΟΥ ΠΡΩΤΟΤΥΠΟΥ ΤΩΝ ΟΔΗΓΙΩΝ ΕΛΛΗΝΙΚΆ ...